Blog

Automatic Shampoo Filling Machine Guide: How to Choose the Best Shampoo Filling Line for Cosmetics Manufacturing in 2026

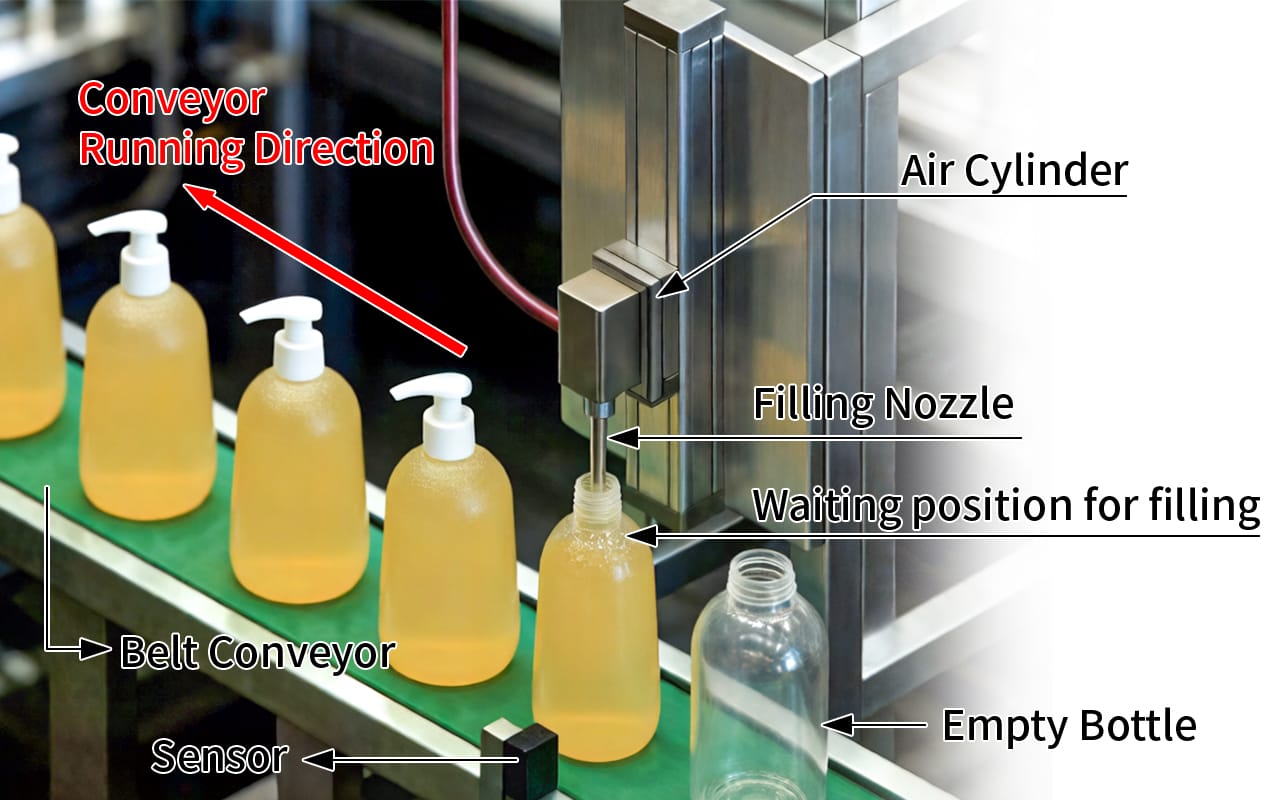

Industry Challenges in Shampoo Production: Why Choosing the Right Filling Machine Matters As global demand for shampoo and personal care products continues to grow, manufacturers are facing increasing pressure to improve production efficiency, filling accuracy, and hygiene standards. Traditional manual or outdated filling methods often lead to: For cosmetic and personal care manufacturers targeting international markets, an automatic shampoo filling machine is no longer optional—it has become a critical investment for scalable, compliant, and competitive production lines. What Is a Shampoo Filling Machine? A shampoo filling machine is an industrial liquid packaging machine designed to accurately and hygienically fill shampoo…

How to Select the Right Automatic Shampoo Filling Machine for Your Global Production Line in 2026

Are you having trouble growing your business as a professional shampoo manufacturer? Here is the answer! Indeed, growing output calls for more work, more resources, and—above all—filling that is accurate, effective, and waste-free. Shampoo filling machines are obviously made for this use. A shampoo filling machine may speed up the process of filling big containers, cut down on filling time, and save labor and waste expenses. Continue reading this review for more details. Prepare to fully comprehend the features of shampoo filling machines! I. What is a Shampoo Filling Machine? A shampoo filling machine is a packaging device specifically designed…

Global Trends in Cosmetic & Personal Care Packaging Machinery-What B2B Manufacturers Need to Know in 2026

Introduction: The Strategic Role of Packaging Automation From 2024 to 2025, the global cosmetics and personal care industry continued its expansion, primarily driven by growing consumer demand for skincare, hygiene, and household products. Behind this growth, packaging automation and intelligentization have gradually become a strategic focus for B2B manufacturers, moving beyond simple upgrades to production equipment in traditional manufacturing plants. Currently, we have entered the Industry 4.0 era of “Smart Manufacturing in China in 2026.” Modern manufacturers are no longer pursuing isolated, monoblock machines but increasingly rely on integrated and intelligent packaging line solutions that improve efficiency, reduce operational risks, and support long-term scalability. Therefore, for companies targeting international markets, selecting the right packaging machinery supplier has become a crucial business decision. Market Overview of Cosmetic & Personal Care Packaging Machinery Cosmetic and personal care packaging machinery includes a wide range of equipment such as filling machines, capping machines, labeling systems, coding machines, cartoning units, and fully automated production lines. The current trend towards diversified industry markets is evident, with packaging production lines shifting from single-function equipment to integrated packaging production line systems capable of handling multiple processes and achieving continuous workflows. This trend is particularly pronounced in the personal care packaging equipment sector, where consistency, hygiene, stability, speed, and capacity are crucial for brand competitiveness. Key Trends Shaping Modern Packaging Lines 1. Automation and Smart Packaging Line Solutions Automation remains the most influential trend across global manufacturing….