Are you having trouble growing your business as a professional shampoo manufacturer? Here is the answer! Indeed, growing output calls for more work, more resources, and—above all—filling that is accurate, effective, and waste-free. Shampoo filling machines are obviously made for this use.

A shampoo filling machine may speed up the process of filling big containers, cut down on filling time, and save labor and waste expenses. Continue reading this review for more details. Prepare to fully comprehend the features of shampoo filling machines!

I. What is a Shampoo Filling Machine?

A shampoo filling machine is a packaging device specifically designed for batch filling precise quantities of liquid or paste products such as shampoo into fixed-capacity containers. It belongs to the category of liquid filling machines. This machine is highly innovative and possesses advanced functions, capable of automatically filling containers of various sizes simultaneously. Furthermore, its integrated product detection and fixing system effectively reduces overfilling and waste. Based on its level of automation and operation method, it can be divided into manual, semi-automatic, and fully automatic types.

Fully automatic shampoo filling machines have a higher level of automation, often employing linear or rotary designs. They can achieve integrated operations such as automatic bottle loading, filling, sealing, and labeling, making them suitable for large-scale production lines. This type of equipment offers high filling accuracy and high efficiency, can adapt to shampoo products of different viscosities, and supports multi-head simultaneous filling, improving production efficiency.

II. What are the benefits of using a shampoo filling machine for mass production?

TRPACK will explain in detail the numerous benefits a shampoo filling machine can bring to your production operations in the following aspects:

1. Stable Performance:

One of the key advantages of using a shampoo filling machine is its highly stable performance during operation. This prevents container shaking, ultimately achieving accurate filling.

2. Equipment Reliability and Product Compatibility:

Reliability is another key characteristic of this machine. It can fill various large-capacity bottles simultaneously. Furthermore, the machine can quickly switch product lines without changing molds, handling materials of various viscosities, including face masks, creams, and ointments. It is compatible with multiple bottle sizes (100ml-5L).

3. Comprehensive Improvement in Production Efficiency:

Due to the large number of filling nozzles, this machine can fill up to 120 containers per minute, thus rapidly increasing existing output and making it suitable for mass production.

4. Savings in Time and Labor Costs:

With a simple machine interface, the machine can run continuously after only one parameter setup. This stable and uninterrupted filling method ultimately increases the number of filling containers and reduces processing time. Meanwhile, thanks to TRPACK’s new intelligent control system, the shampoo filling machine can be easily operated and maintained by a single person for smooth operation.

5. Cleanliness and Hygiene:

TRPACK’s compact shampoo filling machine is made of high-quality S304 stainless steel to international standards, with zero tolerance for bacterial growth and corrosion. When used in conjunction with our negative ion blow-and-suction bottle cleaning machine, they provide a safe and hygienic processing environment for your sensitive products, ensuring that the products are handled in a sterile environment.

6. Unlimited Availability and Scalability:

The most important advantage of the shampoo filling machine is its scalability. You can leverage TRPACK’s complete product range to select suitable auxiliary equipment to upgrade your shampoo production line. For example, you can integrate fully automatic rotary machines, bottle unscramblers, hoppers, and nozzles to perform heavier tasks.

III. What are the applications of shampoo filling machines?

Shampoo filling machines can process a variety of products from different industries, including:

1. Cosmetics Industry:

The cosmetics industry is the most widespread application area for shampoo filling machines. Various products, including shampoo, hair oil, lotion, foundation, and facial cleanser, can be perfectly filled into jars, bottles, or containers using this machine.

2. Personal Care Industry:

This machine is in high demand among personal care product manufacturers. For example, its upgrade options and high precision in filling viscous liquids have become key indicators for any business operator.

3. Pharmaceutical and Herbal Industries:

With the development of the healthcare industry, the application of filling equipment in the pharmaceutical and herbal industries is becoming increasingly important. People use filling machines to produce various syrups and oral suspensions for treating minor to acute illnesses, and a high-efficiency and hygienic shampoo filling machine is also needed to continue the production of products such as herbs and ointments. Indeed, these solutions are filled into bottles using this equipment.

4. Automotive Industry:

It is worth noting that automotive assembly lines require equipment similar to shampoo filling machines, which can efficiently fill engine oil and lubricants into bottles.

IV. What are the main components of a shampoo filling machine?

The robust structure and stable, efficient operation of a shampoo filling machine are due to the synergistic effect of its heavy-duty mechanical components, ensuring optimal machine performance.

Below is a detailed explanation of the components of a shampoo filling machine:

1. Feed Tank

This part of the machine is the liquid storage tank. Liquid shampoo is poured into the storage tank at once to fill large quantities of containers. It is located at the top of the machine, below which are several storage tanks pre-filled with a fixed dose of shampoo. The shampoo is then dispensed into the containers. TRPACK’s filling machine feed tank is equipped with a liquid level detection device that automatically detects the material level, ensuring complete material discharge.

2. Intelligent and User-Friendly Control Panel

This innovative component of the machine makes the entire mechanism easier to operate. This user-friendly device displays a variety of command options required to execute the machine.

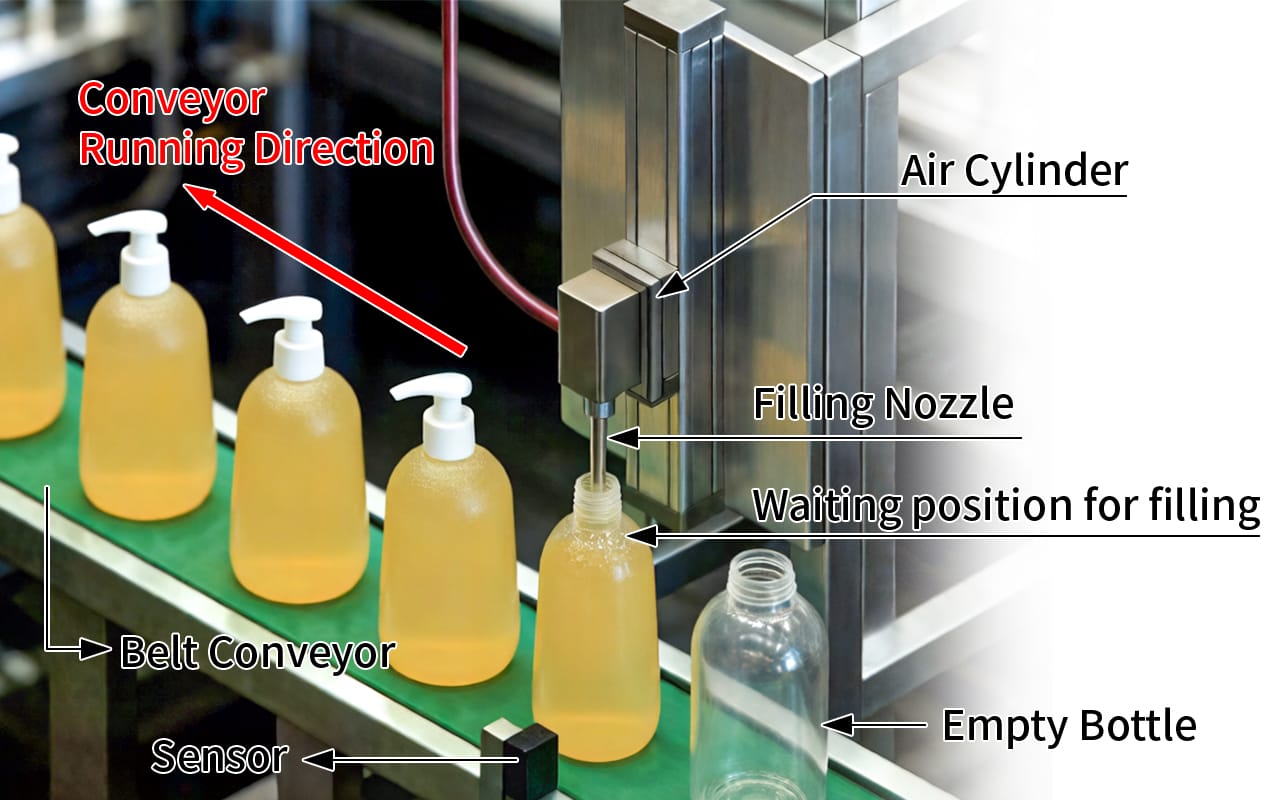

3. Filling Nozzle and Collection Tank

The filling nozzle, also known as a narrow-nose filling head, is connected to the hopper. These components are responsible for precisely drawing shampoo from the hopper and conveying it into containers, preventing waste. Different types of shampoo filling machines are equipped with varying numbers of filling nozzles. The filling heads can be spaced using clips to adjust the spacing according to the bottle size. An independently cylinder-controlled residual liquid collection device is installed below the filling nozzles to ensure that no liquid drips outside the bottle neck after filling stops, ensuring hygienic production and product quality.

4. Electrical Cabinet

The electrical cabinet is a control panel consisting of switches and buttons. Its function is to protect the machine’s electrical components from electric shock.

5. Servo Motor

One or two servo motors are integrated into the machine to regulate the movement of the conveyor belt.

6. Conveying System

It consists of the conveyor belt and the motor driving the conveyor belt. Both are responsible for conveying containers from one end to the filling area and the unloading area, respectively.

7. Support Frame and Base

The S304 stainless steel support frame greatly helps stabilize the filling process. The included round base firmly grips the surface, preventing wobbling.

8. Stop Cylinder

This filling equipment is equipped with an automatic weighing feedback device, which detects the container and sends information to the machine to stop it until the bottle is accurately filled, allowing for real-time adjustment of the filling dosage.

V. An explanation of how a shampoo filling machine operates(Working Principle )

A shampoo filling machine must adhere to a particular operating method in order to finish the standardized filling of shampoo, just like any mechanical equipment. These operational principles are explained by the following points:

1. Loading Paste or Liquid

Filling the hopper with shampoo lotion or other necessary ingredients is the first stage in the shampoo filling process. An operator or an integrated system can accomplish this automatically.

2. Configuring the Parameters

The touchscreen control panel now allows users to adjust the machine’s operating parameters. The conveyor belt speed, the dose time per administration, and the container’s filling level are a few examples of these settings.

3. The process of serialization

To start the machine, just push the power button after determining the dimensions. Eventually, this will turn on the conveyor belt and every other part of the machine. The filling station will receive empty containers in a sequential manner.

4. Filling with Shampoo

When the containers reach below the filling nozzle, sensors will detect their precise position below the nozzle, and then the required amount of shampoo will be filled into the containers through the nozzle.

5. Bottles Output

Finally, once all containers are full, if connected to the production line, the conveyor belt will transport them to the next process; otherwise, they will be unloaded, and operators can manually remove them for labeling and capping, etc.

VI. What types of shampoo filling machines are there?

Shampoo filling machines can be divided into the following categories, which will be described in detail below:

1. High-viscosity Filling Machine

TRPACK fully automated servo high-viscosity filling machine is a specialist piece of automated equipment used to fill thick liquids, pastes, and gels for the everyday chemical industry. It is used to make toothpaste, shampoo, skincare products, and cosmetics. Thanks to its servo motor-driven piston cylinder filling technology, our automatic filling machine has a more intelligent and user-friendly design, uses less air, and fills at a steady rate. The machine is made entirely of SUS304 stainless steel, while the parts that come into touch with materials are made of SUS316L stainless steel. Users who work with chemicals on a daily basis or who require frequent material changes and cleaning will find it ideal. It can be used to quantitatively fill various bottled pastes and liquids automatically.

2. Gear Pump Filling Machine

TRPACK follow-up gear pump filling machine is a highly automated liquid filling equipment that combines gear pump core technology with a dynamic follow-up filling process. It mainly serves production lines that require high-precision and high-efficiency filling, and is especially suitable for quantitative packaging of oils, detergents, acid and alkali solutions, highly corrosive liquids, as well as non-particulate liquids such as cosmetics and food.

3. Flow Meter Filling Machine

TRPACK flowmeter filling machine is appropriate for packing materials including oils, emulsions, and aqueous solutions that have good flowability and no foaming. Additionally, the machine’s structure is in-line. It makes use of a touch-screen human-machine interface with PLC programmable control. A valve and flowmeter connection regulates filling, increasing accuracy and preventing leaks. It has a straightforward design, dependable and steady operation, high production efficiency, robust adaptability, and simple metering specification change.

4. Self-flowing Corrosion-Resistant Filling Machine

Materials having good flowability, like emulsions and aqueous solutions, can be packaged using the TRPACK atmospheric pressure corrosion-resistant filling machine. The machine uses a timed metering filling principle, a constant liquid level (constant speed), and an in-line structure (corrosion-resistant PP frame) to ensure exact filling. Its touch-screen human-machine interface and PLC control make operation simple and convenient. Additionally, the apparatus has a proprietary electronic weighing feedback control system that allows for fully intelligent operation and does away with the necessity for human dosage adjustment.

VII. What types of containers can a shampoo filling machine fill?

1. Classification by container shape:

Shampoo filling machines can fill various bottle shapes, such as:

- Round bottles

- Square bottles

- Flat bottles

- Irregularly shaped bottles (oval, sloping-shoulder, custom-shaped bottles)

- Wide-mouth bottles, Narrow-mouth bottles

Multiple bottle types can be accommodated by changing the bottle guide device, positioning mold, and adjusting the clamps.

2. Classification by capacity range:

Common filling sizes include:

- Small capacity: 30ml / 50ml / 100ml (travel size, trial size)

- Medium capacity: 200ml / 300ml / 500ml (mainstream retail size)

- Large capacity: 1L / 2L / 5L (commercial size, family size, refill size)

Some industrial-grade shampoo filling machines can support 10L or even larger containers.

3. Classification by Container Material:

(1) Plastic Bottles (Most Common)

- PET Bottles

- PE / HDPE Bottles

- PP Bottles

Commonly used for shampoos, conditioners, shower gels, hand soaps, etc. Highly adaptable, corrosion-resistant, and suitable for high-speed automated production lines.

(2) Glass Bottles

- Suitable for high-end personal care products or export-oriented cosmetic packaging

- Filling machines can be equipped with anti-drip filling heads and buffer conveying systems to prevent bottle breakage.

(3) Tubes

- Plastic tubes, aluminum-plastic composite tubes

- Commonly used for travel-sized shampoos, conditioners, and conditioning creams

Usually requires a tube filling and sealing machine

VIII. What equipment is needed for a complete shampoo filling machine production line?

- Fully automatic bottle unscrambler

- Automatic capping machine

- Servo tracking capping machine

- Labeling machine

- Cigarette packaging machine

- Cartoning machine

- Robotic palletizer

IX. What factors should be considered when purchasing the best shampoo filling machine to meet your production line needs?

If you are planning to purchase a shampoo filling machine, remember that this machine will change the fate of your business. However, choosing the best option is up to you.

To help you make a choice, we have listed some important factors that must be considered:

Machine operating specifications:

Your primary focus should be on checking the machine’s operating specifications. For example, you can check the machine’s speed, its adaptability to different containers, and filling accuracy.

Production requirements:

Another factor to consider is examining your current production line. This will help you analyze the production ratio. If the production ratio is high and you expect to further increase output, then a fully automatic machine would be a better choice. Conversely, if your production scale is moderate, a semi-automatic shampoo filling machine can be selected.

Machine Quality:

To understand the quality of the machine, you can check the company’s information and look for its quality certifications. CE and ISO are common quality certification bodies used to supervise the production of high-quality products and equipment. All TRPACK products are certified to international standards.

Warranty Certificate:

If you’ve invested a significant amount of money, obtaining warranty service is crucial. Usually, the manufacturer will provide a warranty certificate; if not, you should proactively request one as proof of quality assurance.

Customer After-Sales Support:

In most cases, the machine we use will suddenly stop working, and we can’t find the problem. Only the machine’s developer knows the real reason. You need to contact the supplier, which is only possible if you’ve considered the company’s customer support services.

Conclusion:

In summary, a shampoo filling machine is a highly efficient tool that accurately measures the amount of shampoo used and fills it into different containers. This equipment can bring you benefits in many ways, such as reducing waste, saving time, and most importantly, increasing production efficiency. Therefore, if you are looking to purchase a shampoo filling machine to increase your business profits, please contact us immediately through our website!