Industry Challenges in Shampoo Production: Why Choosing the Right Filling Machine Matters

As global demand for shampoo and personal care products continues to grow, manufacturers are facing increasing pressure to improve production efficiency, filling accuracy, and hygiene standards.

Traditional manual or outdated filling methods often lead to:

- Inconsistent filling volume

- Raw material waste

- High labor costs

- Low production capacity

- Difficulty meeting export regulations (CE, GMP, ISO standards)

For cosmetic and personal care manufacturers targeting international markets, an automatic shampoo filling machine is no longer optional—it has become a critical investment for scalable, compliant, and competitive production lines.

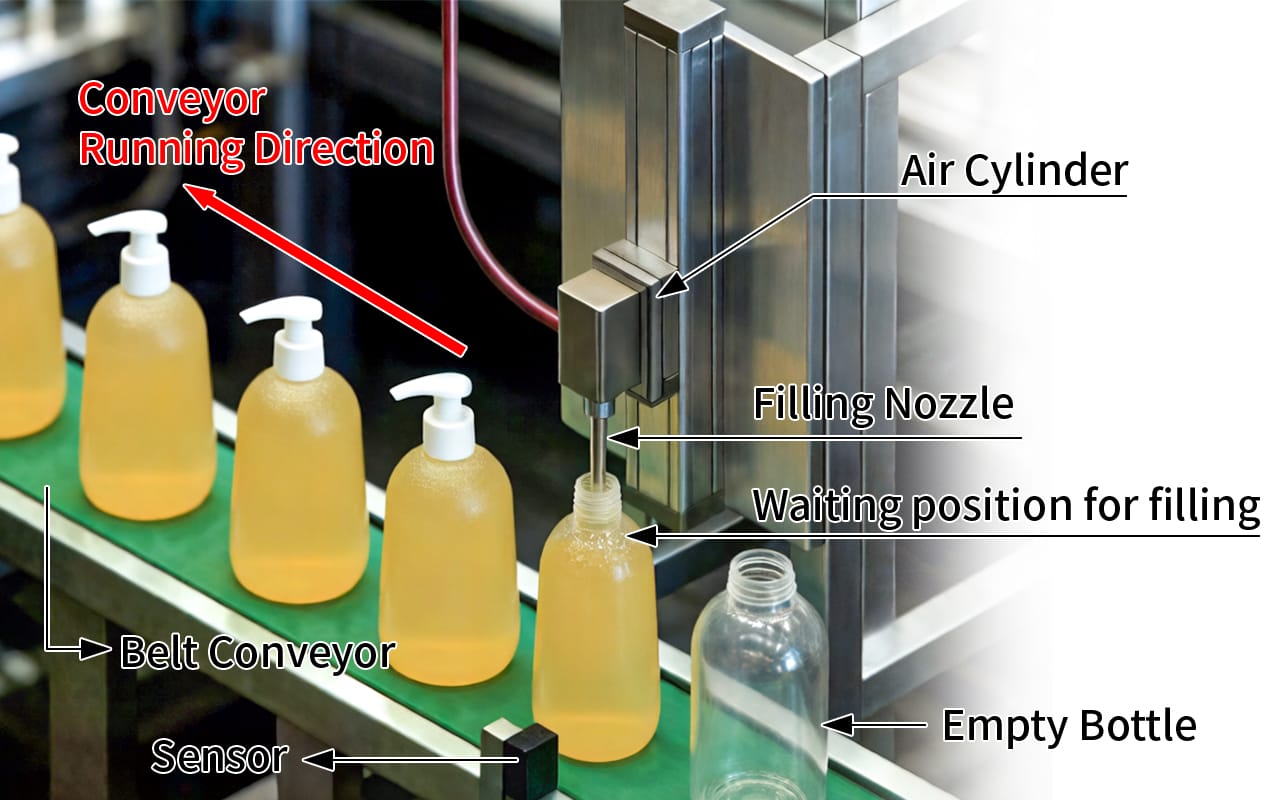

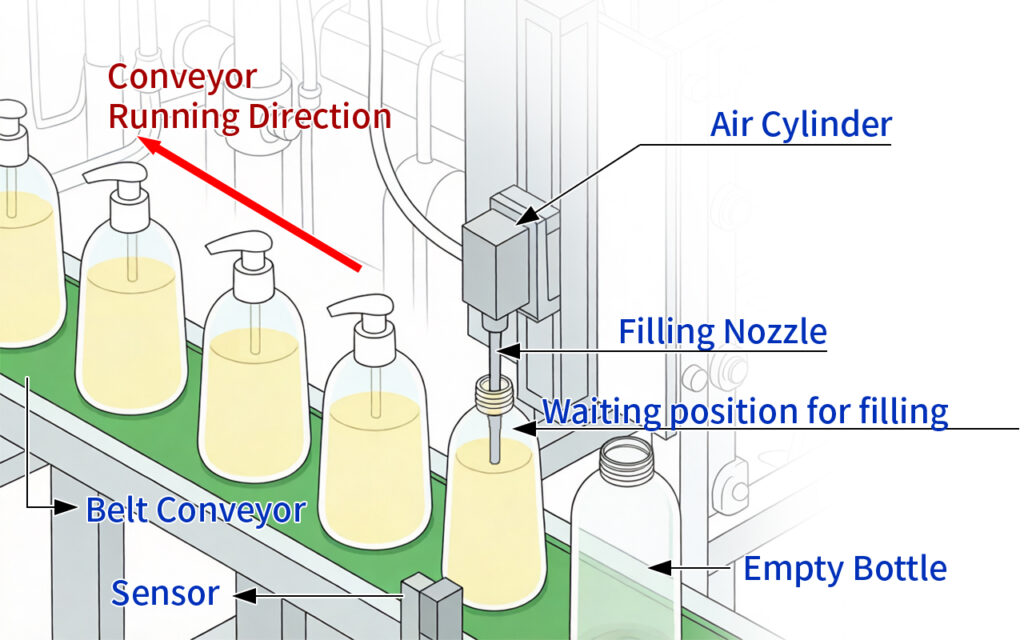

What Is a Shampoo Filling Machine?

A shampoo filling machine is an industrial liquid packaging machine designed to accurately and hygienically fill shampoo and other viscous liquid products into bottles, tubes, or pouches.

It belongs to the category of liquid filling machines for viscous products and is widely used in:

- Cosmetics manufacturing

- Personal care production

- Household cleaning products

- Pharmaceutical and herbal liquid packaging

According to the automation level, shampoo filling machines can be classified into:

- Semi-automatic shampoo filling machines

- Fully automatic shampoo filling lines

These machines ensure stable performance, precise dosing, and flexible bottle compatibility for modern cosmetics production lines.

Key Benefits of Automatic Shampoo Filling Machines for Mass Production

1. High Precision Filling & Reduced Product Waste

Advanced machines use servo piston filling systems and anti-drip nozzles to achieve filling accuracy within ±0.5%.

This ensures consistent product volume, minimizes material loss, and improves overall product quality.

Keywords: high precision shampoo filling machine, servo piston filling machine

2. Flexible for Multi-SKU & Bottle Types

Modern shampoo bottling equipment supports:

- Bottle sizes from 30ml to 5L (or larger)

- Round, square, flat, and irregular-shaped bottles

- Quick changeover without replacing molds

This flexibility allows manufacturers to handle multiple SKUs efficiently.

Keywords: shampoo bottling machine for different bottle sizes, multi-head filling machine

3. High Production Efficiency & Labor Cost Reduction

Fully automatic shampoo filling lines can reach speeds of up to 120 bottles per minute, operated by only one technician.

Continuous automatic operation significantly reduces manpower requirements while increasing output.

Keywords: fully automatic shampoo filling line, industrial filling machine

4. Hygiene & International Compliance

Machines are built with SUS304 or SUS316L stainless steel for all product-contact parts and can be equipped with:

- CIP cleaning systems

- Anti-contamination filling nozzles

- Enclosed safety structures

They comply with CE, ISO, and GMP standards, making them suitable for export-oriented production.

Keywords: cosmetics filling equipment, GMP liquid filling machine

Industries Using Shampoo Filling Machines

Shampoo filling machines are widely applied in:

- Cosmetics & Personal Care Industry Shampoo, conditioner, shower gel, hand soap, lotion, serum

- Household Cleaning Products Liquid detergents, disinfectants, sanitizers

- Pharmaceutical & Herbal Liquids Syrups, suspensions, medicinal liquids

Keywords: liquid packaging machinery for personal care, shampoo production line

Types of Shampoo Filling Machines by Technology

1. Servo Piston Filling Machine (High Viscosity)

Best for thick and viscous products such as shampoo, conditioner, creams, and gels.

Advantages:

- High accuracy

- Stable filling

- Easy cleaning

- Suitable for frequent product changeovers

Keywords: servo piston shampoo filling machine

2. Gear Pump Filling Machine

Suitable for oils, detergents, acid and alkali liquids, and corrosive materials.

Advantages:

- High-speed filling

- Long service life

- Strong adaptability

Keywords: gear pump liquid filling machine

3. Flow Meter Filling Machine

Ideal for low-foaming and free-flow liquids such as emulsions and aqueous solutions.

Advantages:

- Accurate flow control

- Simple structure

- PLC touch screen operation

Keywords: flow meter filling machine for shampoo

4. Corrosion-Resistant Gravity Filling Machine

Designed for emulsions and water-based liquids with good flowability.

Advantages:

- Constant liquid level control

- Intelligent weighing feedback

- Chemical resistance

Keywords: corrosion resistant filling machine

What Types of Containers Can a Shampoo Filling Machine Handle?

By Shape

- Round bottles

- Square bottles

- Flat bottles

- Irregular-shaped bottles

- Wide-mouth and narrow-mouth bottles

By Volume

- Small: 30ml / 50ml / 100ml

- Medium: 200ml / 300ml / 500ml

- Large: 1L / 2L / 5L

- Industrial: up to 10L or more

By Material

- Plastic bottles: PET, PE, HDPE, PP

- Glass bottles (for premium cosmetic packaging)

- Tubes: plastic or aluminum-plastic composite

- Pouches: refill bags and spout pouches

Keywords: shampoo filling machine for plastic bottles, shampoo pouch filling machine

Complete Automatic Shampoo Filling Line Configuration

A full shampoo filling production line may include:

- Automatic bottle unscrambler

- Shampoo filling & capping machine

- Servo tracking capping machine

- Labeling machine

- Cartoning machine

- Robotic palletizer

This integrated solution ensures fully automated production from empty bottle to finished carton.

Keywords: automatic shampoo filling line, shampoo production line solution

How to Choose the Best Shampoo Filling Machine for Your Production Line

1. Production Capacity

Evaluate current output and future expansion plans (bottles/hour).

2. Product Characteristics

Consider viscosity, foam level, and whether liquids are corrosive.

3. Bottle Types

Ensure compatibility with your bottle shapes and sizes.

4. Quality & Certification

Choose machines with EU CE, ISO, etc. certification.

5. Supplier Service & Customization

Look for suppliers offering:

- Custom solutions

- Installation guidance

- Remote technical support

- Long-term spare parts supply

Keywords: how to choose shampoo filling machine, shampoo filling machine supplier

Why Choose TRPACK as Your Shampoo Filling Machine Supplier?

Changzhou Terry Packing Sic-Tech Co., Ltd., (TERRY PACKING or TRPACK) as a high-tech enterprise, is deeply involved in the filling and packaging field, providing integrated solutions for design, processing, manufacturing, sales, and service.

TRPACK provides not just machines, but complete shampoo production line solutions for manufacturers worldwide.

- Years of experience in cosmetic packaging machinery

- Exported to multiple global markets

- Customized filling line solutions

- Full after-sales service system

- International quality certifications

Conclusion & Call to Action

Investing in the right automatic shampoo filling machine is not just about increasing filling speed—it is about ensuring product quality, reducing production costs, and building a scalable production line for global markets.

Whether you are launching a new shampoo brand or upgrading your existing production facility, TRPACK offers customized, reliable, and compliant filling solutions tailored to your exact production needs.

Contact us today to get a free quotation and technical proposal for your shampoo filling production line.

Request a customized solution for your shampoo bottling project now.