GGZ Series Automatic High-Viscosity 500-5L Liquid Filling Machine

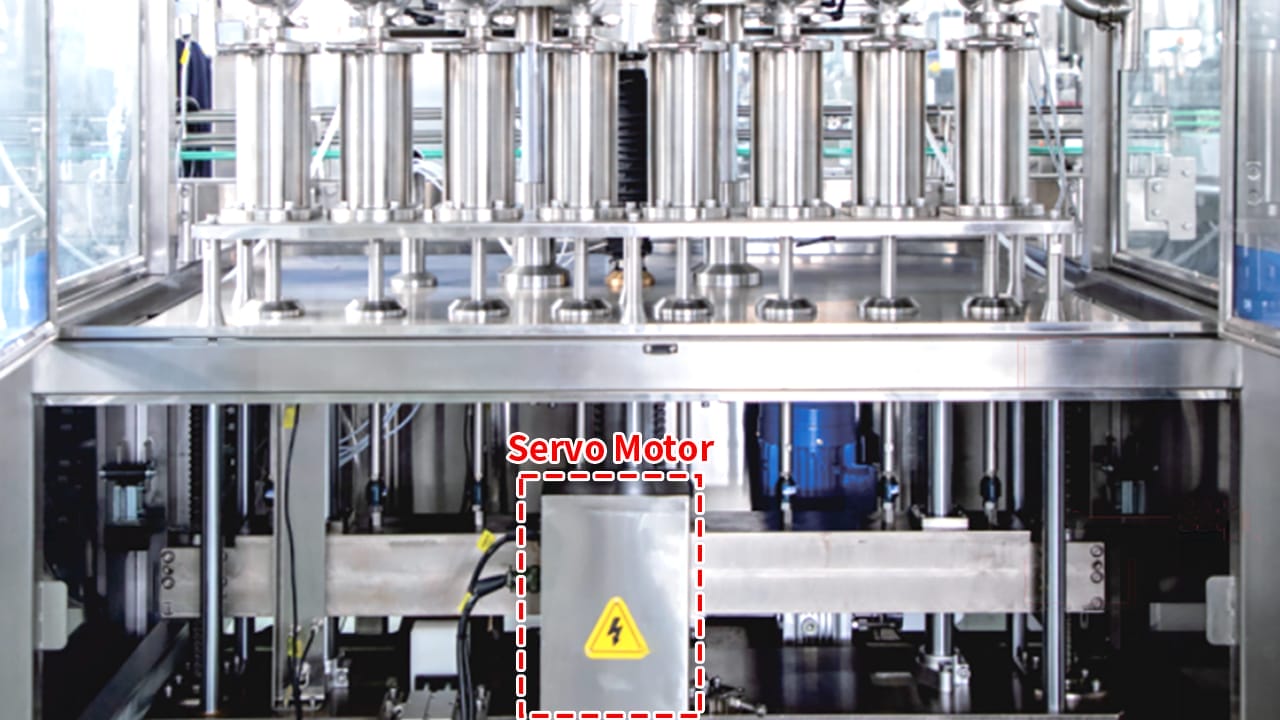

GGZ fully automatic servo high-viscosity filling machine is one of the intelligent filling production line series independently developed and manufactured by TRPACK. This machine adopts a servo motor-driven piston cylinder filling method, resulting in stable filling speed, low air consumption, and greater intelligence and user-friendliness. The entire machine is manufactured using SUS304 stainless steel, while parts in contact with materials are made of SUS316L stainless steel. It is suitable for automatic quantitative filling of various bottled pastes and liquids, and is applicable to the daily chemical industry or users with frequent material changes and cleaning requirements.

Filling Head

Filling Volume

Features:

1. GGZ high-viscosity filling machine is widely used for automatic filling of 50-1000mL bottles in industries such as fine chemicals, daily chemicals, and oils.

2. The filling unit features a demountable cylinder structure that completely empties the material from the tank, effectively preventing cross-contamination and enabling quick and easy seal replacement.

3. PLC programming controls a servo motor-driven synchronous belt paired with a stable dual-screw lifting mechanism, ensuring high-precision piston stroke movement for accurate filling.

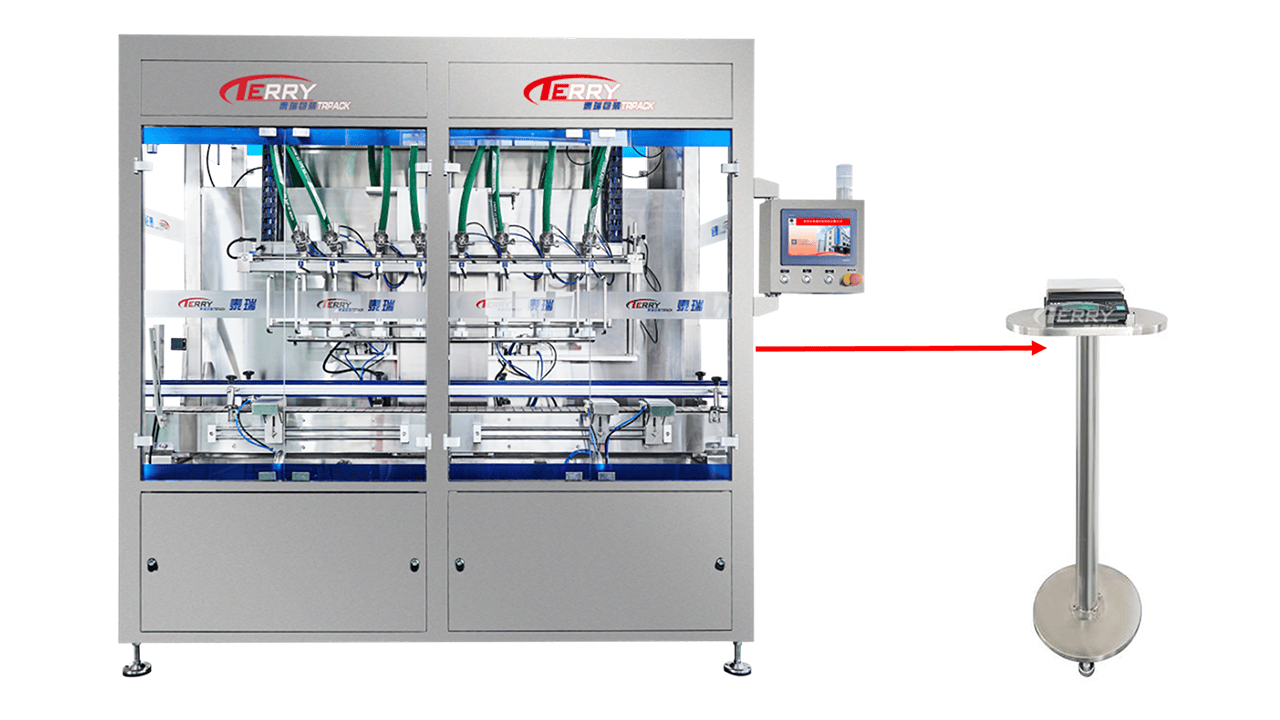

4. Motor-driven filling heads allow height adjustment via the touchscreen for quick and convenient operation.

5. The curved bottom design of the filling machine's material hopper ensures complete material discharge with no dead corners or residue buildup.

6. Electronic weighing system enables one-touch dose adjustment.

7. Sanitary-grade piping and quick-connect fittings facilitate easy adjustment, disassembly, and cleaning.

Application:

For Cosmetics and Pharmaceuticals: This includes lotions, perfumes, bath oils, hand soaps, and shampoos.

For Household and Industrial Products: This includes dishwashing liquids, dish soaps, laundry detergents, cleaning agents, disinfectants, and bleaches.

Samples:

Specification:

| Filling Head | 8 |

| Filling Volume | 100-1000ml |

| Filling Accuracy | 100-200ml±1g ;201-500ml±1.5g ;501-1000ml±2g;Customized |

| Filling accuracy varies according to the characteristics of the materials, the filling volume, and the feeding device. | |

| Applicable Bottle Type | Round Bottle: Φ40-95mm; Bottle Height:80-230mm |

| Tetragonal Bottle: Length 40-95mm; Width 40-95mm; Height 80-230mm | |

| Customization Accept | |

| Production Capacity | 100ml≥50bottles/min;500ml≥40bottles/min;1000ml≥25bottles/min |

| Actual production capacity may vary slightly depending on factors such as product material characteristics, filling volume, and operator proficiency. | |

| Air Supply Pressure | 0.6 ~0.8Mpa |

| Use dry and clean compressed air. | |

| Power Supply | AC380V Three Phase50hz |

| Total Power | 2.5KW |

| Air Consumption | 200 L/min |

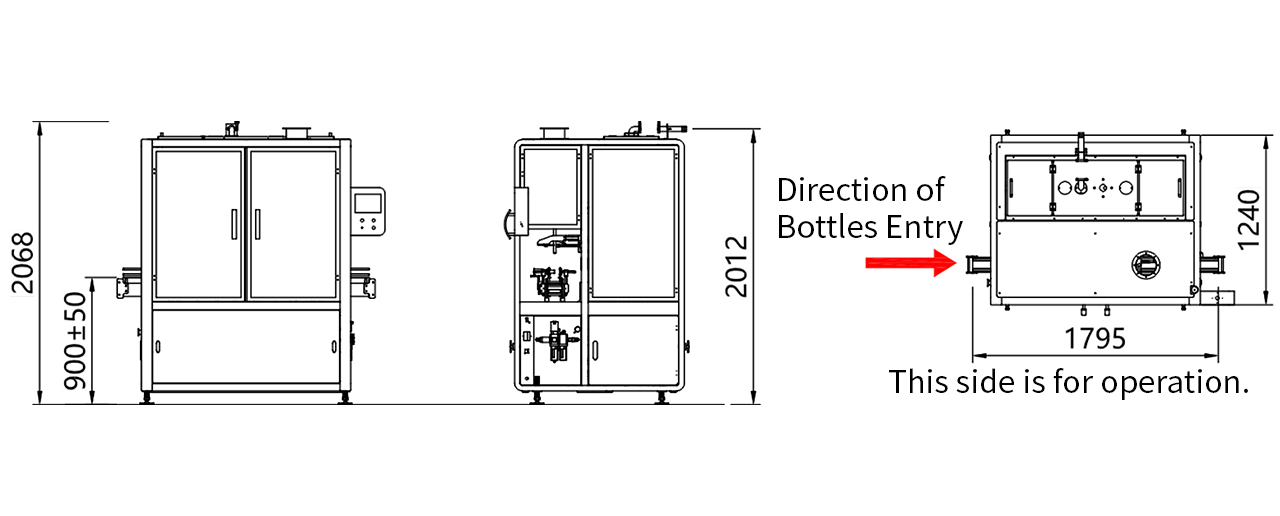

| Overall Dimensions (Main Machine) |

1795×1240×2068mm(L×W×H) |

| Overall Weight | 1100 KG |

Function:

1. Utilizes servo motor filling for high precision and adjustable filling speed, enabling customized filling rates for different materials.

2. Features servo motor-controlled submerged filling heads: Filling heads automatically submerge into bottles, rising synchronously with liquid levels to prevent overflow of high-foam materials.

3. The filling unit features a demountable cylinder structure, enabling complete emptying of the material cylinder. This effectively prevents cross-contamination and facilitates quick and easy seal ring replacement.

4. The filling nozzle incorporates an internal plug design to prevent dripping. Each filling head set is equipped with a bottle mouth clamping function to prevent impact on the bottle opening.

5. Spacing between filling heads adjusts via snap-fit components according to bottle size, offering quick and convenient adaptation.

6. An independently pneumatic-controlled drip collection tray is installed beneath the filling head to prevent residual liquid dripping onto the bottle mouth after the filling head closes.

7. Equipped with an automatic weighing feedback system for automatic dose adjustment (used for dose calibration during setup; not for online checkweighing. During normal operation, filling accuracy can be verified through sampling).

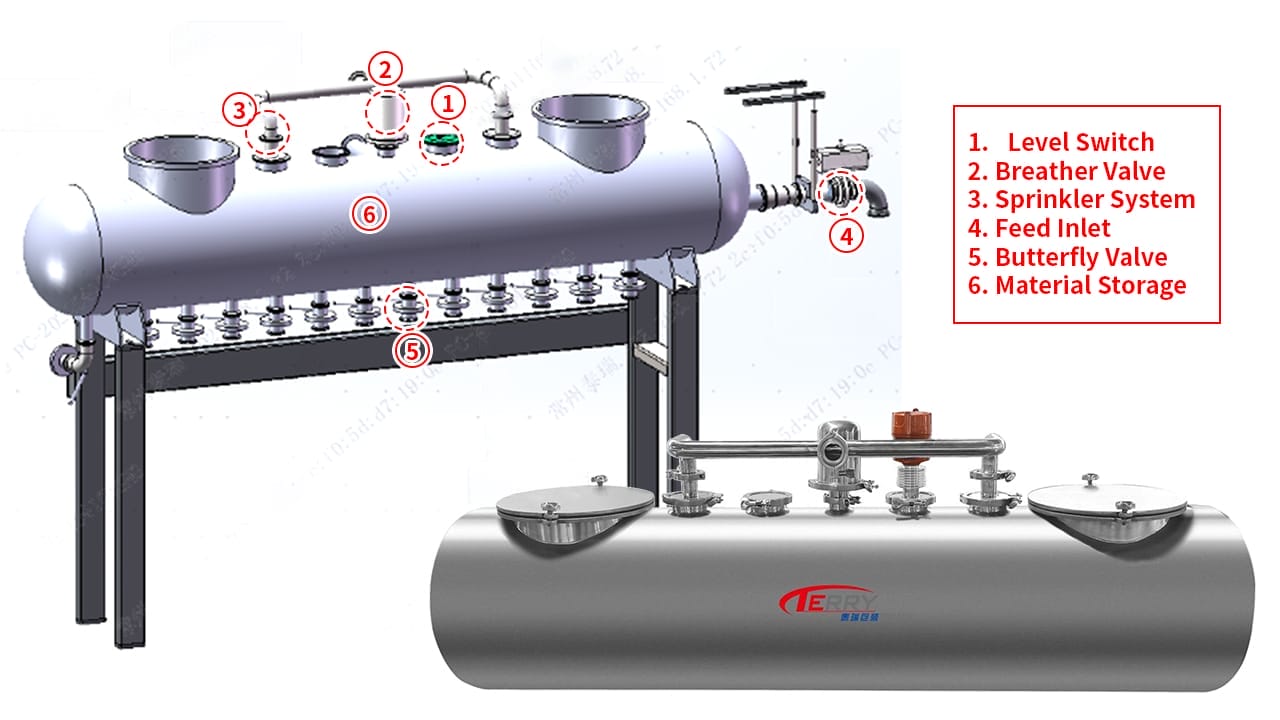

8. Utilizes an open-bottom curved hopper for material loading. The hopper interior features a mirror finish for aesthetic appeal and easy cleaning. All hoppers are equipped with liquid level detection devices for automatic monitoring of material levels.

Specification:

| Constituent Parts | Primary Functions |

| Level Switch | Ceases material replenishment at high liquid levels and alerts for replenishment at low levels |

| Breather Valve | Maintains material tank pressure equilibrium to minimize liquid evaporation |

| Sprinkler System | Online cleaning capability |

| Feed Inlet | Replenishment Channel |

| Butterfly Valve | DN40 butterfly valve for switching material flow between the tank and piston cylinder |

| Material Storage | Loads materials for filling operations |