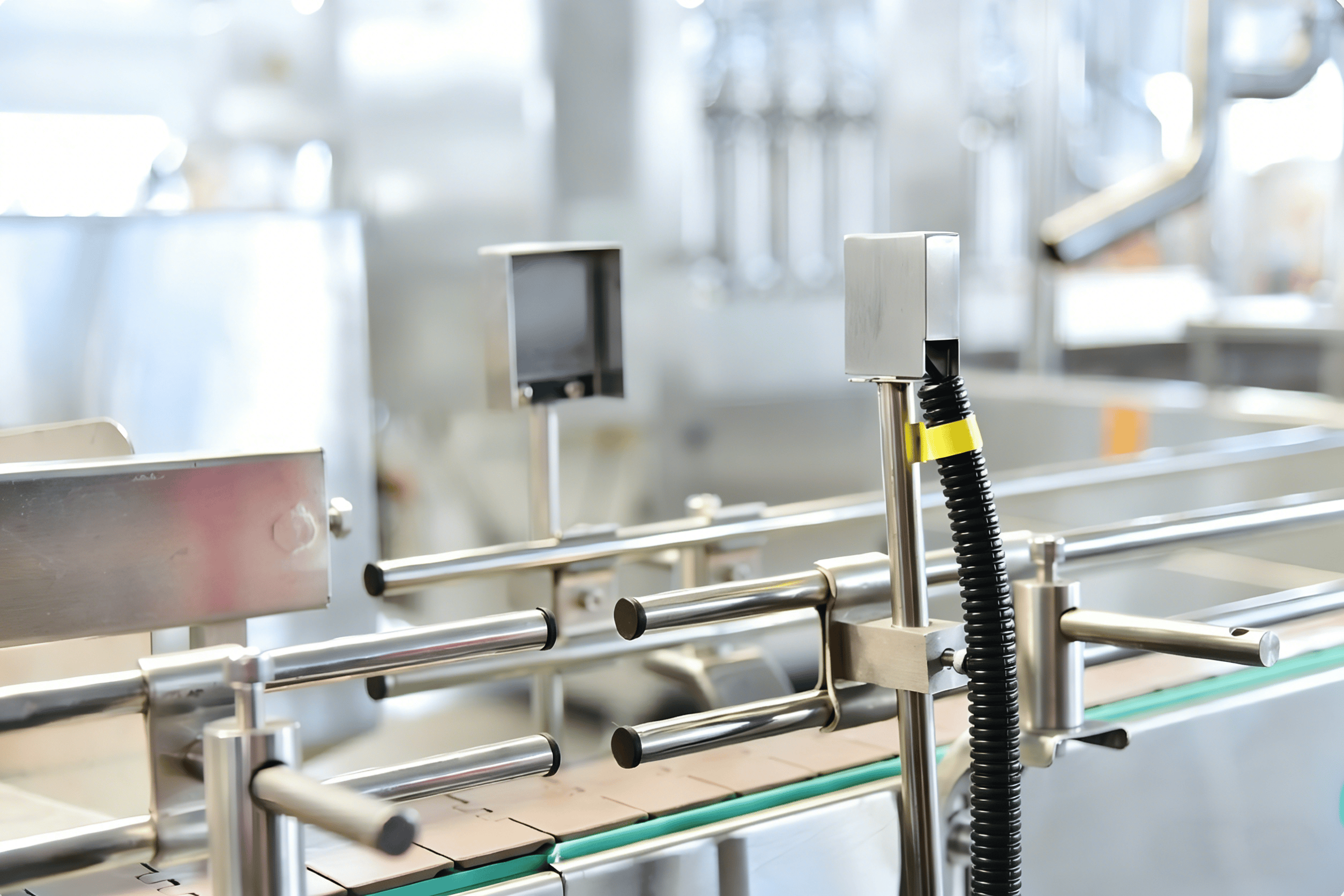

TR-LP Series Automatic 100-1L Bottle Unscrambler Machine

The LP Series (for 1L bottles) Fully Automatic Bottle Unscrambler is made up of:

– a top part that feeds the bottles in;

– a disc that sorts the bottles;

– a part that rejects the bottles;

– a part that sorts the bottles again;

– a part that rejects the bottles by pouring; and

– an electrical box.

A lot of bottles, which are not sorted, are put into the bottle sorting disc by the upper bottle feeding device. They are then taken to the bottle sorting area by the conveyor belt. This allows the bottles to be moved up to the user’s conveyor belt. This model is small, simple, and uses well-known technology. It is also stable and reliable. It is used in many industries to package bottles automatically.

Applicable Bottle

Filling Volume

Production Capacity

Application:

For Cosmetics and Pharmaceuticals: This includes lotions, perfumes, bath oils, hand soaps, and shampoos.

For Household and Industrial Products: This includes dishwashing liquids, dish soaps, laundry detergents, cleaning agents, disinfectants, and bleaches.

Samples:

Specification:

| Filling Head | 8 |

| Filling Volume | 100ml -1000ml |

| Filling Accuracy | 100-200ml±1g ;201-500ml±1.5g ;501-1000ml±2g;Customized |

| Filling accuracy varies according to the characteristics of the materials, the filling volume, and the feeding device. | |

| Applicable Bottle Type | Round Bottle: Φ40-95mm; Bottle Height:80-230mm |

| Tetragonal Bottle: Length 40-95mm; Width 40-95mm; Height 80-230mm | |

| Customization Accept | |

| Production Capacity | 100ml≥50bottles/min;500ml≥40bottles/min;1000ml≥25bottles/min |

| Actual production capacity may vary slightly depending on factors such as product material characteristics, filling volume, and operator proficiency. | |

| Air Operated Resource | 0.6 ~0.8Mpa |

| Use dry and clean compressed air. | |

| Air Consumption | 200 L/min |

| Power Supply | AC 380V Three Phase50hz |

| Total Power | 2.5KW |

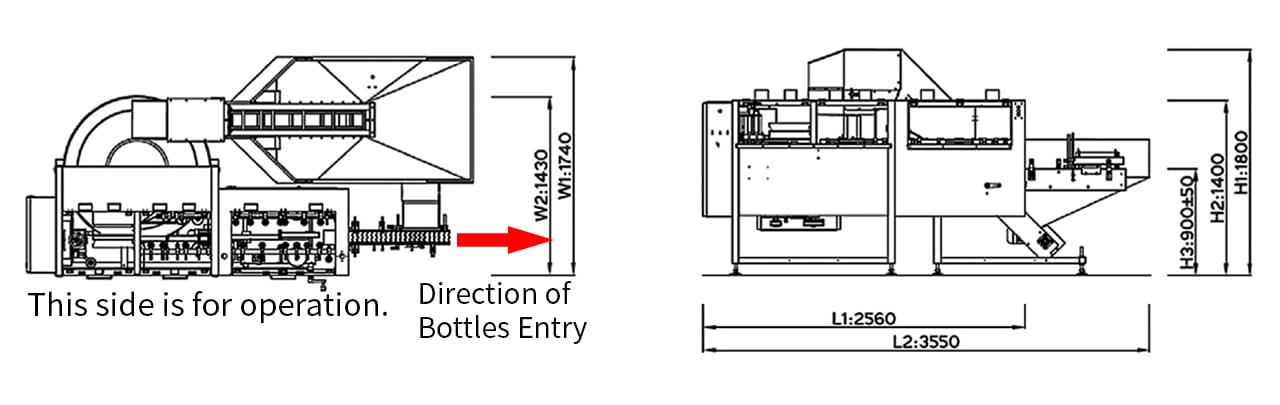

| Overall Dimensions (Main Machine) |

1795×1240×2068mm(L×W×H) |

| Overall Weight | 1100 KG |

Function:

1. Convenient Operation: Compact structure, small floor space, simple overall design, with only three operation buttons. The operation is simple and can be completed with one click. It has good versatility, and can be used with bottles ranging from 50ml to 1000ml.

2. Flexible Specification Change:Changing the specifications does not require any mold replacement. The adjustment is convenient and fast. When changing the specifications, only the number of belts in the rotating disc and the spacing of the bottle sorting components need to be adjusted.

3. Production Visualization: A large area is covered with an organic glass cover, which provides excellent visibility and can be fully opened.

4. Production Safety: All the acrylic covers are equipped with sensor switches. The machine can only be started when the acrylic cover is fully closed. If any acrylic door is opened during operation, the machine will stop running. This ensures both safety and reliability.

5.Automatic Bottle Loading Function: Simply pour the bottles into the bottle loading machine. The rotating disc is equipped with detection photoelectric sensors, which enable automatic bottle loading when there are insufficient bottles and stop the loading when there are enough bottles. If there are no bottles in the loading machine, an automatic alarm will sound, and no manual intervention is required.

6.Adjust The Conveyor: When the bottles on the downstream conveyor belt are congested, stop the bottle sorting process; when the downstream conveyor belt operates smoothly, resume the bottle sorting, achieving a perfect connection with the downstream packaging equipment, and enabling unmanned operation of the entire machine.

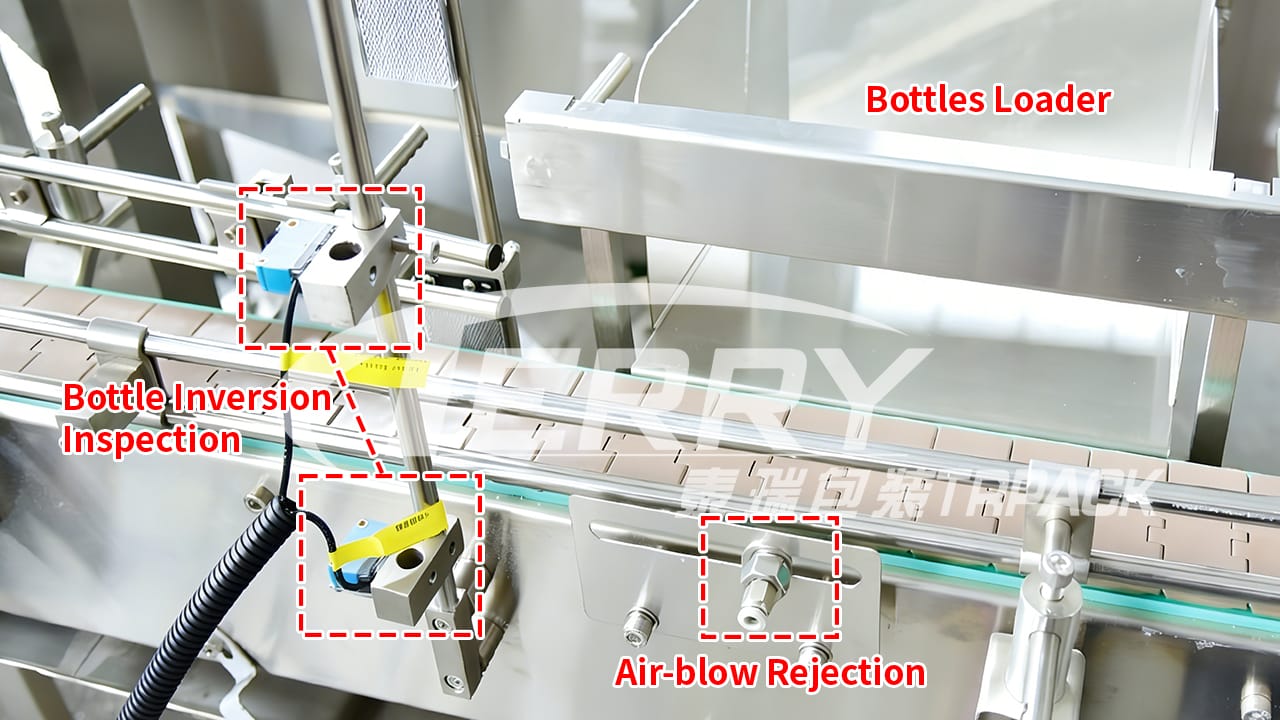

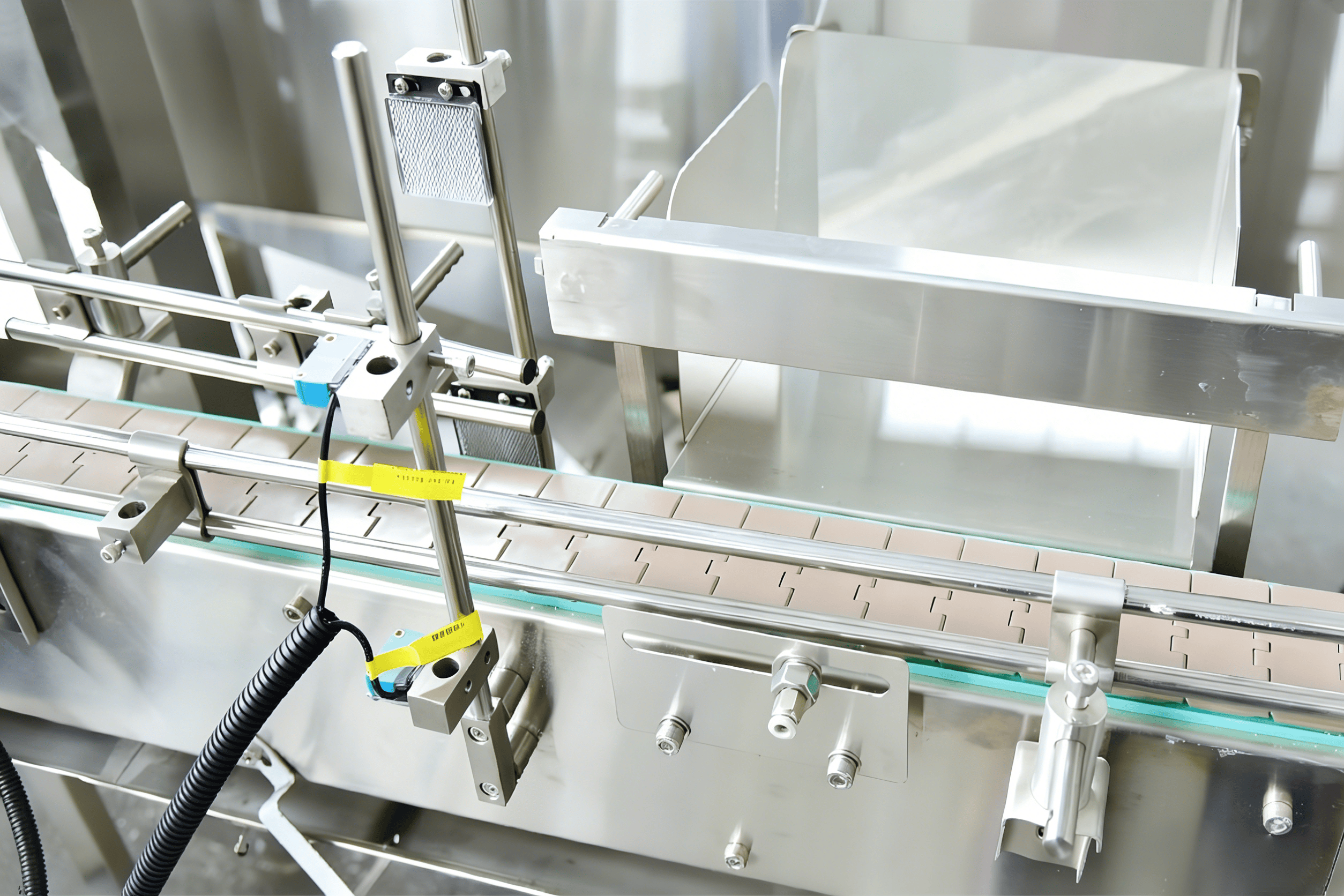

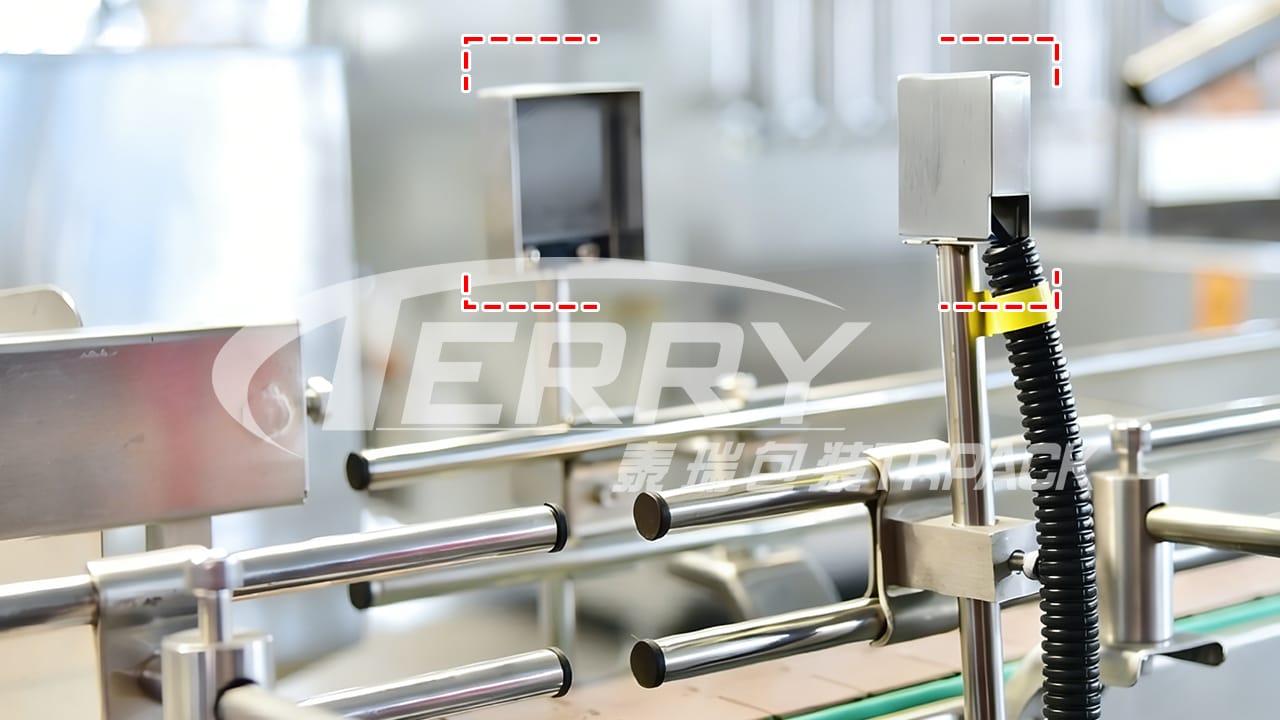

7. Equipped With Bottle-Reversal Elimination Device: When bottles are sorted and a reversed bottle is detected, the photoelectric sensor triggers the elimination device, which kicks the reversed bottle back into the bottle-arranging machine and re-sorts the bottles without the need for manual intervention. (This function is optional.)