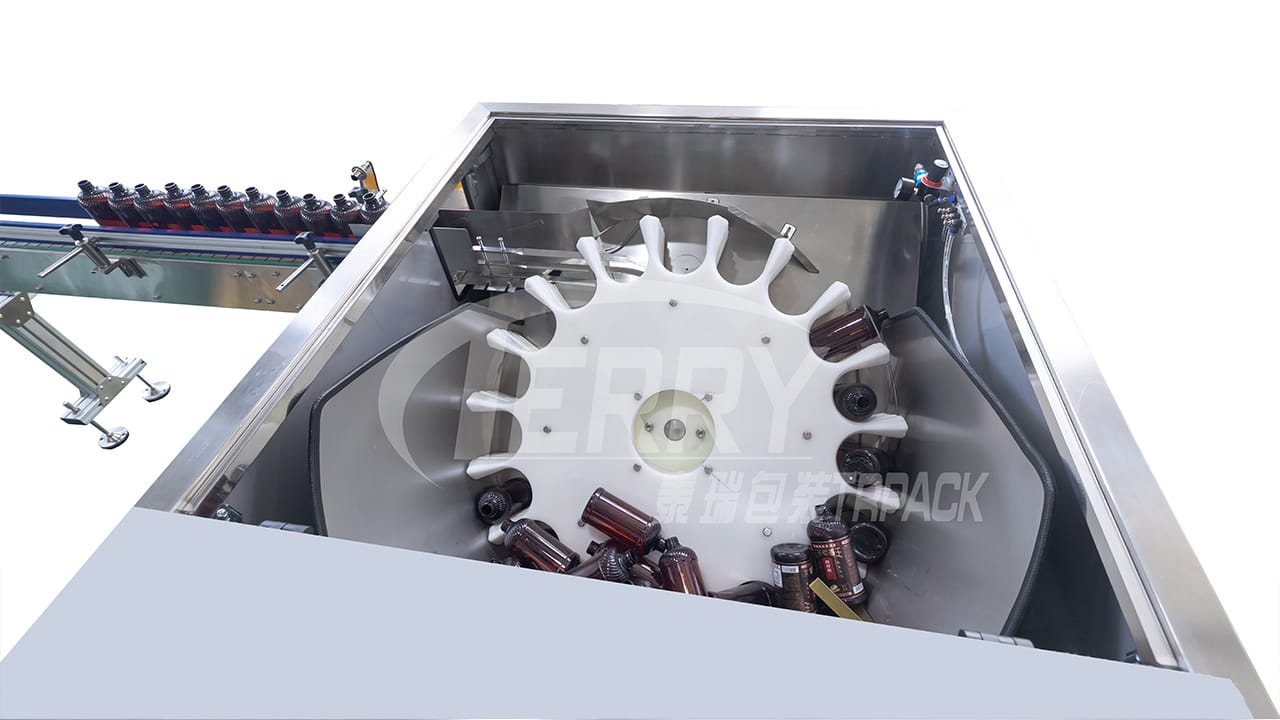

TR-LP Series Automatic 500ML Bottle Unscrambler Machine

The LP Series(for 500ml bottles) Fully Automatic Bottle Unscrambler is an integrated mechanical and electrical device. It is easy to operate and maintain, and provides reliable performance. It is equipped with a quantitative control detection device for bottle discharge and an overload protection device.

This machine is fully intelligent, and the noise level is less than 70 dB. All of the machine’s materials are made of high-quality 304 stainless steel, meeting GMP requirements. The mechanical reverse bottle correction mechanism unifies the bottle mouths. It is also equipped with a bottle storage device which greatly improves production efficiency. The machine has three stepless speed regulating motors. One of these is used to adjust the speed of the bottle sorting disk.

The faster the speed of the bottle sorting disk, the faster the bottle discharge speed; conversely, it will be slower. At the outlet of the machine, an Optonix photoelectric switch detects the presence of full bottles on the subsequent conveyor belt. If this occurs, the bottle sorting disk motor will automatically stop. If a shortage of bottles is detected, the motor will automatically start again.

Applicable Bottle

Filling Volume

Production Capacity

Application:

For Cosmetics and Pharmaceuticals: This includes lotions, perfumes, bath oils, hand soaps, and shampoos.

For Household and Industrial Products: This includes dishwashing liquids, dish soaps, laundry detergents, cleaning agents, disinfectants, and bleaches.

Samples:

Specification:

| Applicable Bottle Diameter | Ø40mm-60mm (Various Specifications Option) |

| Filling Volume | 50ml -500ml |

| Production Capacity | ≥80 bottles/min (Using 50ml as an example, the production capacity depends on the packaging material and the operator's proficiency) |

| Power Supply | 220V 50Hz, 0.5Kw |

| Overall Dimensions (Main Machine) |

1650×900×1050mm(L×W×H) |

| Overall Weight | about 210 KG |

Function:

1. Storage Bottle Mechanism: The storage bottle space is large, the storage capacity is high, and it is very convenient to replenish or remove bottles.

2.Bottle Unscrambler: Bottle unscrambler is simple in design and operates stably.

3.Automatic Coordination Function: This machine is equipped with an automatic coordination function - when the bottle inspection photoelectric sensor detects a bottle congestion in front of the filling machine, the bottle sorting machine will stop running. When the bottle inspection photoelectric sensor detects that the congestion has disappeared, the bottle sorting machine will resume operation.