TR-X Inline Automatic Flip Bottle Air Rinsing Machine

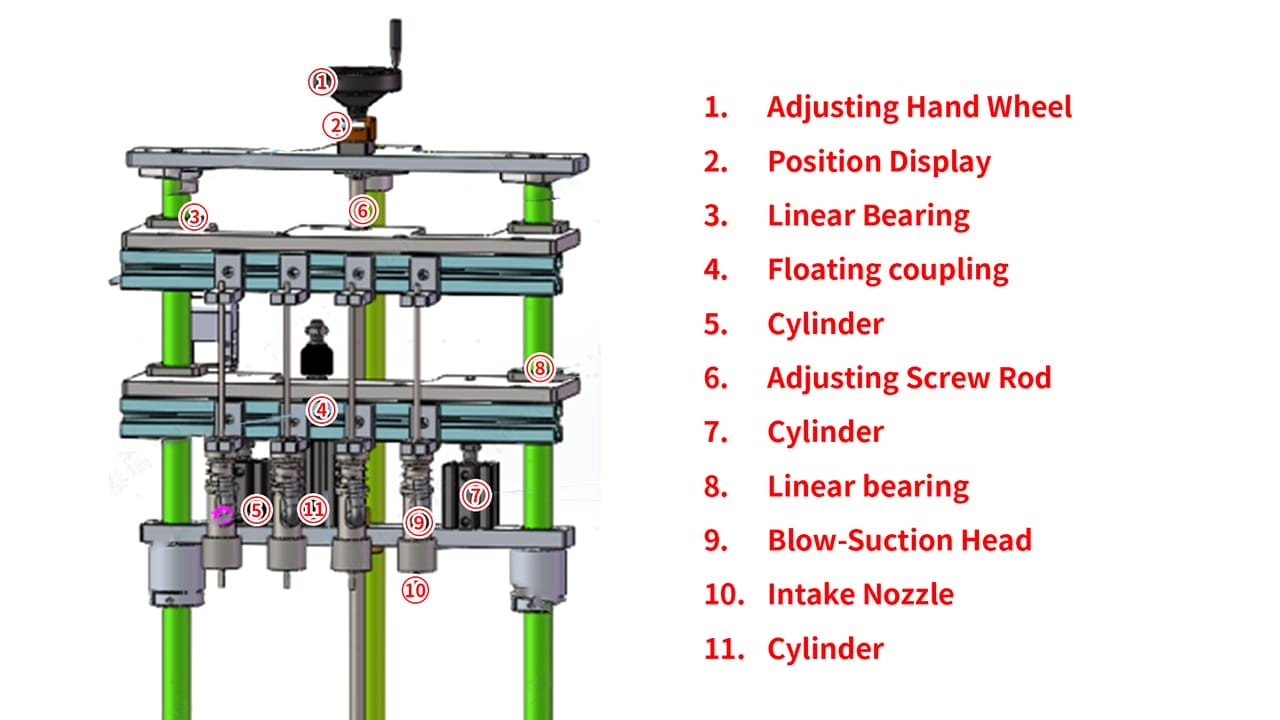

CX-4 type submerged blow-suction device has a total of 4 suction and blowing heads. It blows in a gas with negative ions for static electricity removal (with filtration possible) from the bottom of the bottle, while the pressure block at the bottle opening creates a vacuum, thus sucking out the dust. It is equipped with a bottle opening positioning device.

Applicable Bottle

Filling Head

Production Capacity

Features:

1. Efficient dry cleaning, with guaranteed cleanliness.

(1.) Integrated Blowing and Suction, Thorough Dust Removal: Use clean compressed air to blow away dust inside the bottle, and simultaneously vacuum to suck away impurities. Combined with an ion generator to eliminate static electricity, it avoids secondary adsorption of dust, effectively removing micro-particles, dust, water droplets, etc., ensuring the cleanliness of the bottles before filling.

(2.) No Secondary Pollution: The collected dust during suction is centrally collected and discharged, not recycled. The fully sealed design also reduces dust leakage, protecting the production environment and the health of operators.

(3.) Higher Efficiency: Compared to the water washing + drying process, there is no need to wait for drying, and it can directly connect with filling, and can be matched with the production line for continuous operation, improving the overall production efficiency.

2. Energy conservation and environmental protection, with low operating costs.

(1.) Significant Water Saving: The entire process of dry cleaning does not require water, avoiding the cost of wastewater treatment during water washing. This is particularly suitable for areas with water shortages or scenarios with strict water quality requirements.

(2. )Lower Energy Consumption: Only compressed air and electricity are consumed. Compared to the heating and drying stages of water washing equipment, energy consumption is significantly reduced, making it more economical for long-term operation.

(3.) Green And Environmentally Friendly: No wastewater or chemical cleaning agents are discharged. It complies with environmental protection standards and helps enterprises achieve clean production.

3. Strong adaptability, convenient operation and maintenance.

(1.) Good Bottle Type Compatibility: By adjusting the needle height, cylinder baffle distance, etc., it can quickly adapt to different specifications of glass bottles and plastic bottles, and the type change is convenient.

(2.) High Automation Level: PLC control + human-machine interface, supporting automatic bottle entry and exit, no action without bottle, automatic counting and other functions, reducing manual intervention and lowering the error rate of operation.

(3. ) Simple Maintenance: The structure is simple, using durable materials such as 304 stainless steel, easy to disassemble and clean, low failure rate, and low maintenance costs and downtime losses.

4. Safe and stable, adaptable to various scenarios.

(1.) Robust Safety Measures: Some models are equipped with a door-stop mechanism, and the body is made of stainless steel which is corrosion-resistant and easy to clean, meeting the hygiene and safety standards of the food and pharmaceutical industries.

(2. )Wide Application Scope: It is widely applicable in industries such as beverages, food, pharmaceuticals, cosmetics, and chemicals, meeting the dust removal requirements for different types of bottles.

Application:

For Cosmetics and Pharmaceuticals: This includes lotions, perfumes, bath oils, hand soaps, and shampoos.

For Household and Industrial Products: This includes dishwashing liquids, dish soaps, laundry detergents, cleaning agents, disinfectants, and bleaches.

Samples:

Specification:

| Blow-Suction Head | 4 |

| Applicable Bottles | According to the customer's packaging material customization request |

| Production Capacity | ≥50 bottles/min * Actual production capacity may vary depending on product size, packaging material type, material properties, etc. |

| Air Operated Resource | 0.6 ~0.8Mpa (Use dry and clean compressed air) |

| Air consumption | 200L/Min |

| Voltage | AC 220V 50Hz |

| Power | 1.2KW |

| Overall Dimensions | 800×800×1850mm(L*W*H) |

| Overall Weight | 400 KG |

Function:

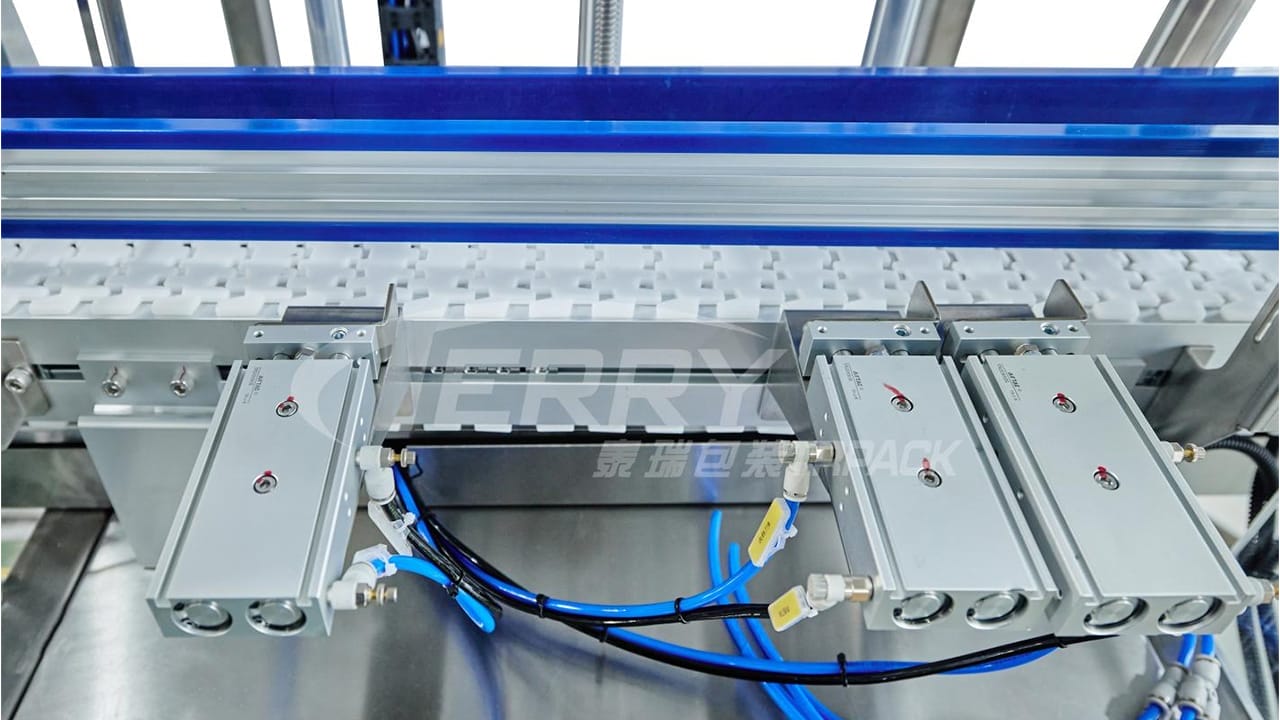

1.Bottle Feeding And Separating Mechanism: The bottle feeding cylinder stopper and the bottle discharging cylinder stopper are used to perform the bottle separation action.

2.Brand negative ion generator and static electricity removal and dust collection system.

3.Adjust the height of blowing and suction and the distance between the suction head: According to the height of the bottle, turn the lifting adjustment handwheel on the lifting system to adjust the distance between the suction head and the bottle mouth. According to the diameter of the bottle, manually adjust the distance between the blowing and suction heads.