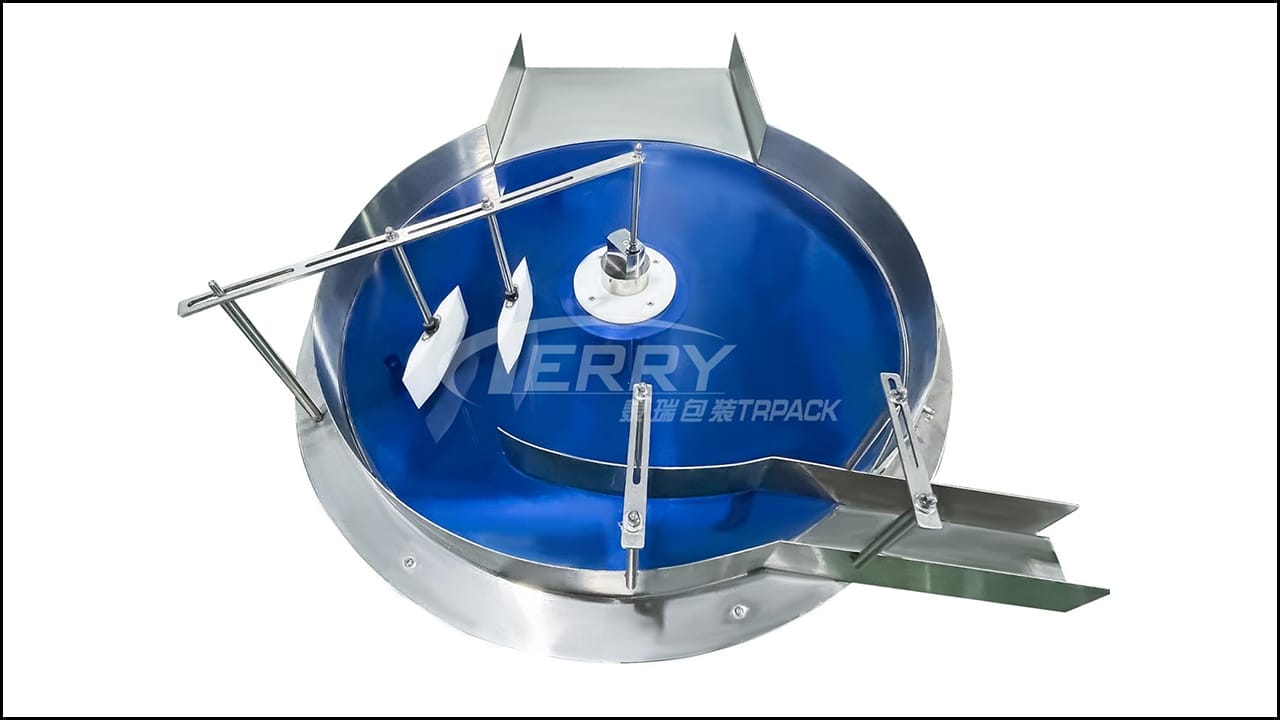

TR-XJP Automatic Rotary Bottle Turntable

The TR-XJP Rotary Bottle Turntable is an automatic bottle feeding platform that uses variable frequency speed control to ensure empty bottles enter the conveyor in sequence. It is an ideal alternative to manual operations. This equipment has a simple structure and can handle both small and large bottles without the need for part replacement; adjustment is sufficient. It is relatively ideal auxiliary production line equipment in China.

Applicable Bottle

Filling Volume

Production Capacity

Features:

1. Simple Structure: The design is straightforward and clear, featuring both bottle buffering and operation convenience.

2. Durable And Reliable: Made of 304 stainless steel, it complies with GMP standards.

3. Flexible Customization: The diameter of the turntable can be customized, allowing for flexible adjustment according to the size of the bottles, with strong applicability.

Application:

For Cosmetics and Pharmaceuticals: This includes lotions, perfumes, bath oils, hand soaps, and shampoos.

For Household and Industrial Products: This includes dishwashing liquids, dish soaps, laundry detergents, cleaning agents, disinfectants, and bleaches.

Samples:

Specification:

| Applicable Bottles | Round Bottle: Diameter Φ40 - 95mm; Bottle Height 80 - 240mm (Plastic bottles, glass bottles, vials, spray bottles, etc.) |

| Production Capacity | 30 - 100 bottles/min The actual production capacity varies depending on factors such as product size and packaging material. |

| Power Supply | About 400W |

| Overall Dimensions | 1200*1200*1000mm(L×W×H) |

| Overall Weight | About 100Kg |

Function:

Automatic Bottle Feeding System: TR-XJP rotary bottle turntable consists of a main rotating disc and a bottle outlet. It is semi-automatic and simple to operate, with no special training required. When changing product types, almost no adjustment is needed. It has stepless speed regulation and a stable speed. According to GMP standards, the entire machine is mainly made of AISI 304 stainless steel and can be modified as required. It can be coordinated and linked with the entire production line and automatically sorts bottles and stops bottle filling according to production conditions.