Mask

Whether you run a single mask packaging product or a wide range of mask packaging, our complete mask packaging range of machines is excellent for companies dedicated to handling mask packaging precisely and aesthetically.

Existing production lines are slow, lowly automated, with high failures and downtime, yielding insufficient output. They can't handle surging orders or rapid new launches, bottlenecking growth. Symptoms: slow cycles, poor machine coordination, heavy manual intervention.

Older equipment uses inefficient drives (pneumatic, high-power motors) and wear-prone structures, wasting electricity and air. Frequent repairs raise costs for parts, technicians, and services, keeping maintenance expenses high.

Poor accuracy, complex setups, and fluctuations cause defects: inaccurate filling, loose caps, misaligned labels, bad seals, damaged film. High defects waste materials, add rework labor, raise costs, and damage brand reputation.

Large lines suit mass single-item production but require lengthy, labor-intensive changeovers. SMEs need frequent switches for varied, small-batch products; replacing molds and adjusting parameters takes hours, with high costs, unfit for flexible manufacturing.

Complex interfaces with jargon intimidate users, demanding extensive training. SMEs lack engineers, facing high costs, operational risks, and reliance on external support for issues.

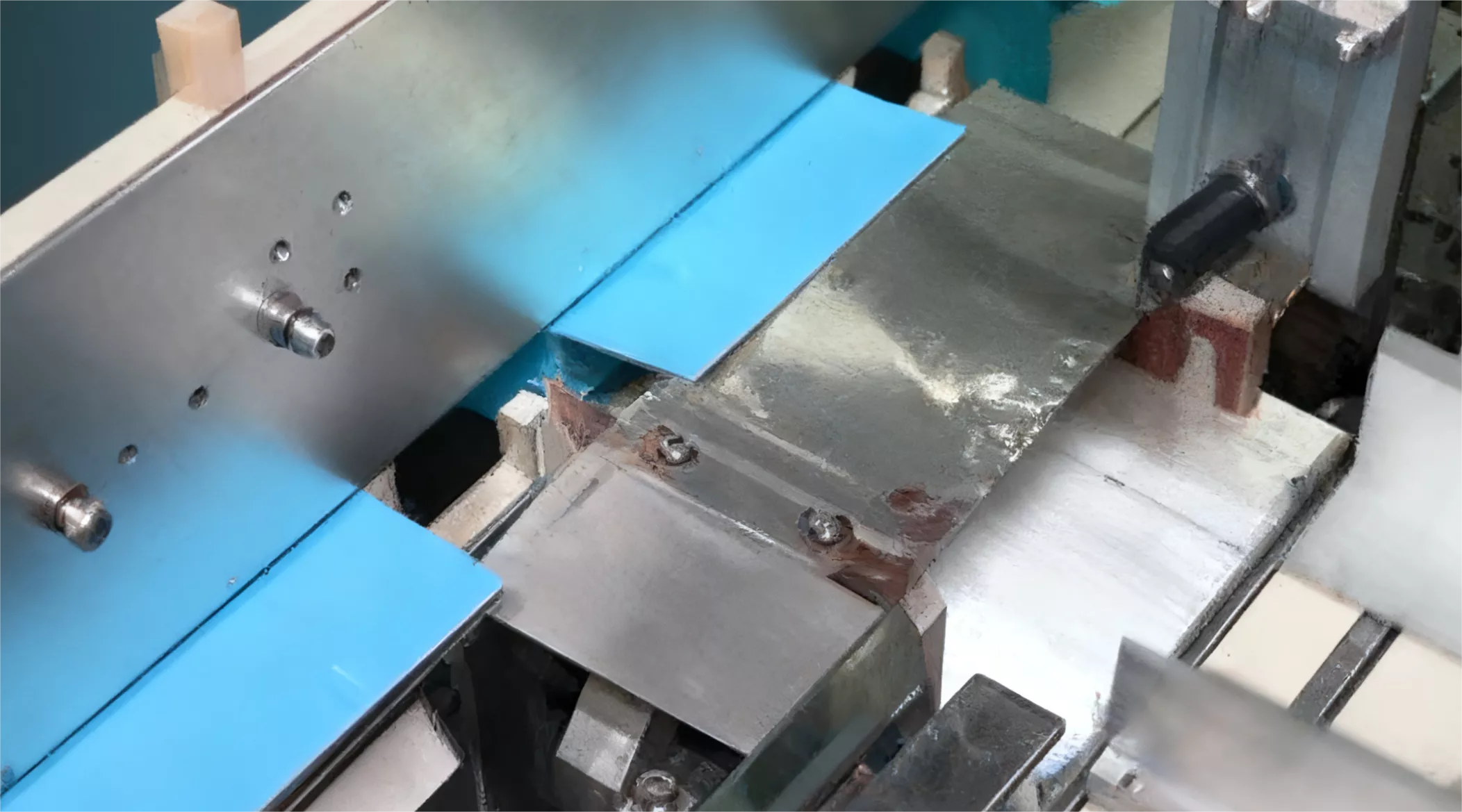

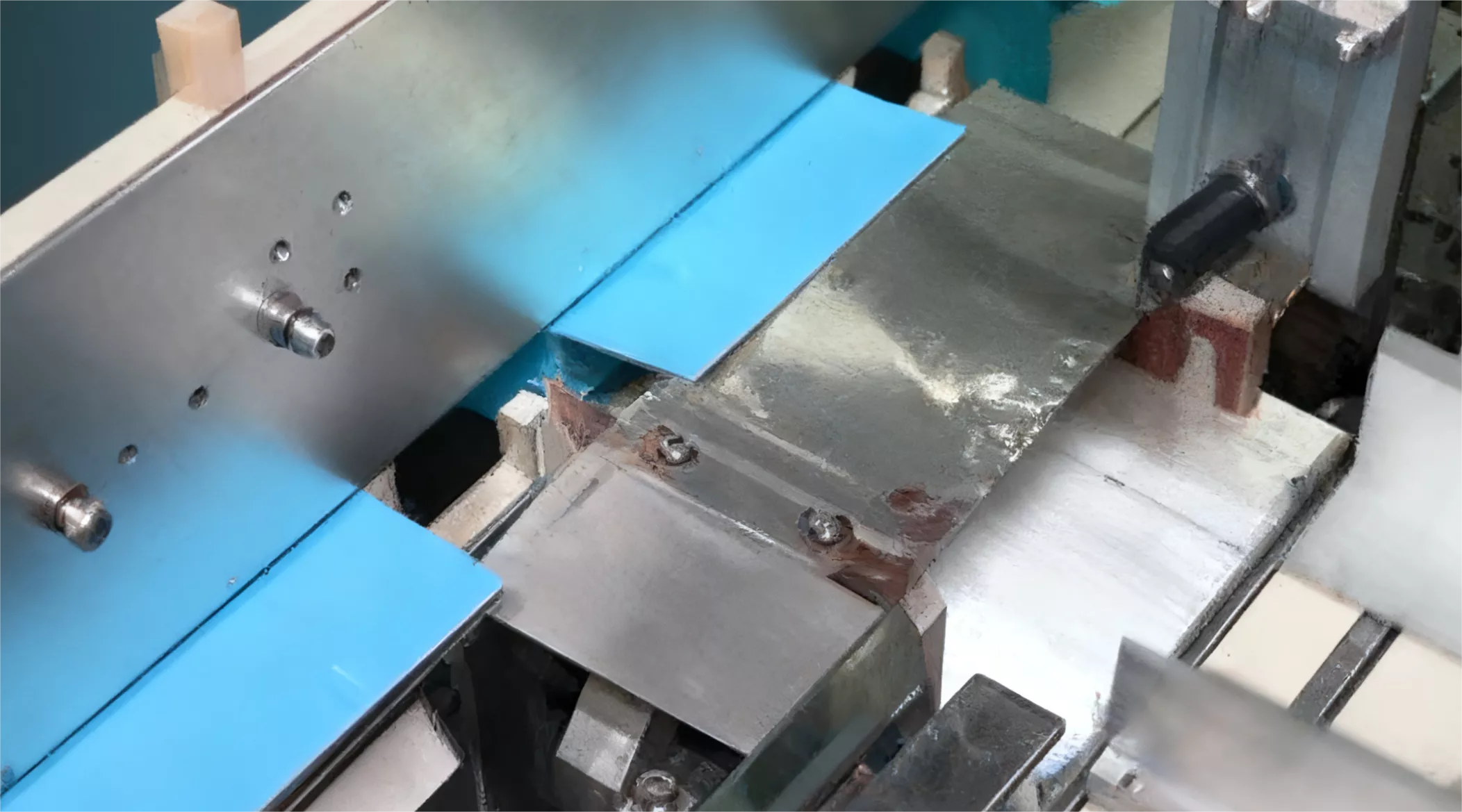

Achieves ±0.1% filling accuracy for essence solutions using servo-controlled pumps compatible with various viscosities. Intelligent sealing ensures complete integrity for aluminum foil and composite films, with vision inspection to prevent leakage. Supports quick changeover between sheet masks, sleep masks, and other packaging types, enabling efficient, contamination-free integrated filling and sealing while enhancing mask packaging quality and line efficiency.

Integrates high-precision labelers with CCD vision systems for accurate front/back labeling of mask pouches and anti-counterfeit labels on boxes. Automatically detects packaging position to ensure bubble-free, aligned labeling. Compatible with various materials including adhesive labels, transparent films, and security labels, meeting diverse packaging needs for sheet masks and cream masks while enhancing brand image and product value.

Cartoner employs adaptive robotic hands and guide mechanisms to handle various mask boxes, outer cartons, and gift sets. Automatically completes box opening, mask placement, insert loading, and sealing. Integrated weight check and QR code scanning ensure packaging integrity and traceability. Flexible design supports quick changeover for mixed packaging and seasonal sets, enhancing packaging versatility.

Utilizes 6-axis robots with 3D vision for automatic case grasping, pattern recognition, and intelligent stacking. Customizes pallet layouts based on storage needs, seamlessly connecting with upstream packaging lines. Handles mixed-size cases simultaneously , improving space utilization by 40% and building a smart logistics loop from packaging to warehouse.

Central control system integrates the entire mask packaging process from filling, pouching, cartoning, case packing to palletizing, enabling unified recipe management, production monitoring, and quality traceability. Compatible with MES/ERP systems for real-time OEE and energy consumption analysis. Features remote diagnostics and predictive maintenance, helping mask manufacturers build Industry 4.0 smart factories and improve overall operational efficiency.

We provide complete packaging solutions for mask products, from R&D to mass production. For new product development and small-batch trial production, we offer cost-effective semi-automatic filling equipment compatible with manual loading and packaging stations. For large-scale production needs, we deliver modular fully automated production lines that enable fully automated operation from essence filling, sheet feeding, sealing, to final output. The equipment features quick changeover capabilities, supporting rapid transition between different mask specifications and significantly enhancing production flexibility.

Our equipment is compatible with various mask packaging formats, including sheet mask pouches, sleep mask jars, and application mask tubes. Packaging specifications can cover the full range from single-use trial packs to multi-piece family packs. For different essence formulations—whether lightweight aqueous solutions, viscous serums, or special functional formulas—stable and efficient packaging is ensured by adjusting filling parameters and production processes, guaranteeing consistent product quality.

The system integrates automatic sheet loading, precise filling, sealing, and online inspection functions. Equipped with high-precision vision inspection systems, it enables real-time monitoring of sheet positioning, essence levels, and packaging seal integrity. Supports automatic feeding and forming of various packaging materials, ensuring end-to-end quality control from primary to secondary packaging, effectively improving product pass rates and production line intelligence.

Leveraging our integration expertise in the skincare packaging field, we offer "Intelligent Mask Packaging Line" customization services. We can seamlessly integrate equipment such as essence preparation systems, sheet handling devices, filling and sealing machines, vision inspection systems, cartoners, and case packing equipment according to your capacity needs and process characteristics. This enables full automation from raw material processing and product packaging to finished goods storage, maximizing overall line efficiency.

Whether you run a single mask packaging product or a wide range of mask packaging, our complete mask packaging range of machines is excellent for companies dedicated to handling mask packaging precisely and aesthetically.