Introduction: The Strategic Role of Packaging Automation

From 2024 to 2025, the global cosmetics and personal care industry continued its expansion, primarily driven by growing consumer demand for skincare, hygiene, and household products. Behind this growth, packaging automation and intelligentization have gradually become a strategic focus for B2B manufacturers, moving beyond simple upgrades to production equipment in traditional manufacturing plants.

Currently, we have entered the Industry 4.0 era of “Smart Manufacturing in China in 2026.” Modern manufacturers are no longer pursuing isolated, monoblock machines but increasingly rely on integrated and intelligent packaging line solutions that improve efficiency, reduce operational risks, and support long-term scalability. Therefore, for companies targeting international markets, selecting the right packaging machinery supplier has become a crucial business decision.

Market Overview of Cosmetic & Personal Care Packaging Machinery

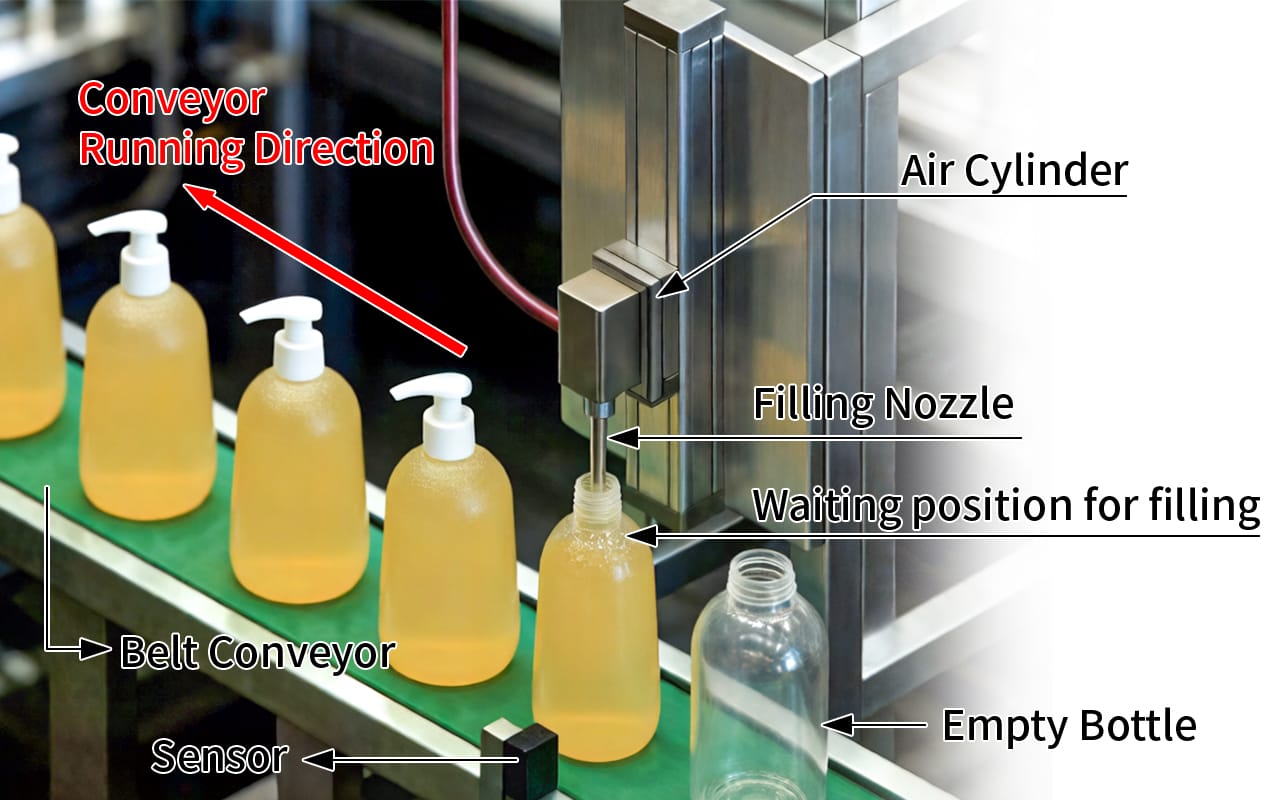

Cosmetic and personal care packaging machinery includes a wide range of equipment such as filling machines, capping machines, labeling systems, coding machines, cartoning units, and fully automated production lines.

The current trend towards diversified industry markets is evident, with packaging production lines shifting from single-function equipment to integrated packaging production line systems capable of handling multiple processes and achieving continuous workflows. This trend is particularly pronounced in the personal care packaging equipment sector, where consistency, hygiene, stability, speed, and capacity are crucial for brand competitiveness.

Key Trends Shaping Modern Packaging Lines

1. Automation and Smart Packaging Line Solutions

Automation remains the most influential trend across global manufacturing. However, the focus has evolved from basic automation to smart packaging line solutions.

Advanced servo control systems, PLC integration, real-time data monitoring, and fault diagnostics allow manufacturers to:

- Improve production line transparency. The entire generation process is traceable.

- A single person can control the entire intelligent automated filling, capping, and sealing bao production line. This reduces labor costs, minimizes human error, and reduces downtime

- Maintain consistent product quality and increase output.

For B2B manufacturers, smart packaging systems are now viewed as a long-term productivity asset rather than a cost expense.

2. Integrated Packaging Lines as the New Industry Standard

An integrated packaging line combines multiple packaging processes—such as bottle unscrambling, filling, capping, labeling, inspection, and cartoning— into a single coordinated system.

Compared to purchasing machines separately, integrated solutions offer:

- Better system compatibility

- Faster installation and commissioning

- Simplified maintenance and operation

As production demands increase, integrated packaging lines have become the preferred solution for manufacturers seeking efficiency and stability.

3. Compliance-Driven Equipment Upgrades

Compliance requirements in Europe, North America, and other regulated markets are driving significant upgrades in personal care packaging equipment

Manufacturers are prioritizing machinery that meets:

- CE certification standards

- FDA and GMP requirements

- Hygienic and safety-focused design principles

For export-oriented companies, compliance directly impacts market access, making certified equipment and experienced suppliers essential.

4. Flexible Production for Multi-SKU Manufacturing

Product diversification is accelerating in the cosmetics and personal care sectors. This has increased demand for flexible and modular integrated packaging lines capable of handling frequent changeovers.

Modern smart packaging systems are designed to support:

- Multiple bottle and container sizes

- Adjustable filling volumes

- Quick mold and format changeovers

Flexibility ensures that manufacturers can respond rapidly to market trends without compromising production efficiency.

Regional Market Insights

In Europe and North America, buyers prioritize high automation, robotic arm control, certified equipment, and smart packaging line solutions with long- term service support.

Southeast Asian manufacturers focus on scalable systems that balance automation and cost efficiency, while African and emerging markets emphasize durability, ease of operation, and stable performance.

Survey of all regions of the world, the end factories for cosmetic and personal care increasingly seek reliable packaging machine manufacturers or suppliers capable of delivering complete integrated solutions rather than standalone equipment.

What Global B2B Buyers Expect from a Packaging Machine Supplier

In 2026, B2B buyers share several common expectations when selecting a packaging machine supplier:

- Proven experience with integrated packaging lines

- Customizable solutions for personal care packaging equipment

- Compliance with international certification standards

- Stable production performance and spare parts availability

- Long-term technical and after-sales support

Suppliers who can provide engineering expertise and turnkey solutions are more likely to build lasting partnerships.

Key global B2B manufacturers and suppliers of cosmetics and personal care packaging machinery to watch:

CHANGZHOU TERRY PACKING SCI-TECH CO., LTD. (TRPACK)

AILEAEROSOL LOM TECH LINER UNIVERSAL

Why Integrated & Smart Packaging Line Solutions Dominate Future Investments

The growing complexity of manufacturing environments has made smart, integrated packaging line solutions the preferred investment choice for B2B manufacturers.

By combining automation, intelligence, and compliance into a single system, integrated packaging lines reduce operational risks while improving overall equipment efficiency. This approach enables manufacturers to scale production with confidence and predictability. Achieve maximum profit.

Conclusion

The future of cosmetic and personal care manufacturing is defined by integration, intelligence, and reliability. For B2B manufacturers, investing in advanced personal care packaging equipment and working with an experienced packaging machine supplier is essential for long-term success.

After reading this article, you should have a basic understanding of the global trends in cosmetics and personal care packaging machinery. Hopefully, this will help cosmetics, skincare, and personal care product factories make informed decisions when purchasing production packaging equipment and enable your partners to maintain a highly competitive production system in the ever- changing international market.

TEERY PACKING (TRPACK) will always be with you.

Welcome to contact us.