TRPACK is ready to tackle any cosmetic and skin care filling and packaging challenge!

Whether your production line consists of a single liquid cosmetic or encompasses multiple liquid or cream cosmetics, we understand that each application requires a unique solution. TRPACK's comprehensive range of fully automated, intelligent filling and packaging machinery for cosmetics is dedicated to providing you with precise, mature, and reliable production line solutions.

- Automated cosmetic filing machine, turnkey packaging lines etc. Accuracy +/- 0.5%.

- Volumetric filling for toner,s lotions, creams, gels, and other skincare products; Explosion-proof vacuum filling for oils and perfume.

- Screw, Trigger, Inner Press, and Valve Crimping Capping machines

- Clear customs with ISO, EU CE certificates

We can provide solutions for these products.....

- Lotion

- Toner

- Serum

- Face Cream

- Cleansing Milk

- Sunscreen Spray

- Perfume

- Essential Oil

- Makeup Remover

- Ampoule

| Product Type | Application Scenarios | Applicable Packaging Bottles | Compatible Material | Core Functional Requirements |

|---|---|---|---|---|

| Emulsion (Liquid Toner, Lotion) | Toner (PET pump bottle), Moisturizing Lotion (PP squeeze bottle), Premium Essence Water (glass dropper bottle) | PET bottles, PP bottles, Glass Bottles, Vacuum bottles | PET (transparent and shock-resistant), PP (strongly resilient), high borosilicate glass (anti-corrosion) | Anti-leakage, easy to press, and quantitative dispensing |

| Cream (in the form of paste / semi-solid) | Gentlewoman Cream (Acrylic Vacuum Bottle), Body Cream (Tube), Travel-sized Cream (Metal Small Can) | Acrylic bottles, glass wide-mouth jars, metal cans, tubes | Acrylic (with good texture), sodium calcium glass (low cost), aluminum alloy (strong sealing ability), five-layer composite hose (anti-leakage) | Strong sealing, anti-contamination, and convenient to use |

| Essential Oil (highly active / prone to oxidation) | Single-ingredient essential oil (dark glass dropper bottle), concentrated essential oil (vacuum vial), compound essential oil (aluminum spray bottle) | Dark glass bottles, aluminum dropper bottles, vacuum vials | Brown / Dark high-boron-silica glass (UV-resistant), food-grade aluminum (with strong barrier properties) | Anti-oxidation, anti-evaporation, precise dosage control |

Problem with cosmetic & skin care Packaging Industry

Low Production Efficiency

The overall process is mainly semi-automatic, and the automation process is not fully developed, with long turnaround times.

The production changeover takes a longtime

Switching specifications for production adjustments requires a large number of personnel and tools, and the compatibility is poor.

It is inconvenient to clean

The disassembly and cleaning process takes a long time and there are many hard-to-reach areas, which fails to meet the GMP requirements.

There are many production personnel

The production line process mainly featuring semi-automatic equipment is rather complex, relying heavily on manual operations. The number of packaging personnel per production line can reach as high as 25 or more.

The process is not perfect

The various production links are not sufficiently continuous and integrated. The turnover is frequent and complex.

Insufficient Quality Control

There are deficiencies in the quality control process, with most of the inspections relying on personnel for identification, which poses quality control risks.

Why choose TRPACK as your cosmetic & skin care filling and packaging partner?

Highly automated production process is adopted, with the overall production capacity reaching50-150 bottles/ minute.

All the replacement parts are of quick-installation and quick-disassembly structure. During the process, no tools are needed and the replacement can be completed quickly.

TRPACK offers two cleaning modes for the industry

Online cleaning: Use CIP cleaning for the material box, connect the spray ball to the cleaning pipe line, set the cleaning mode in the program, and automatically start the cleaning process.

Offline cleaning: Use the production changeover cart form. Install the entire wet part on the cart, and have personnel push the cart to the cleaning room for disassembly and cleaning.

TRPACK's fully automated production line can be easily operated and maintained by 2 to 3 workers, ensuring smooth operation and saving labor costs.

Process Flow: The intelligent control of packaging materials - bottle loading - blowing and suction - filling - inserting inner stopper - capping - pressing the cap -marking - packaging - unpacking - packing - sealing the box - all these processes are fully automated.

The proportion of manual assembly is high, and the defect rate of bottle body formation exceeds5%. The rework cost has increased by 20%.

Related Client Case Show

Fully Automatic Filling Lines for Lotion and Cream, Automatic Bottle Loading and Unloading Machine

Application Scenarios:Creams, Solid Masks, Eye Creams.

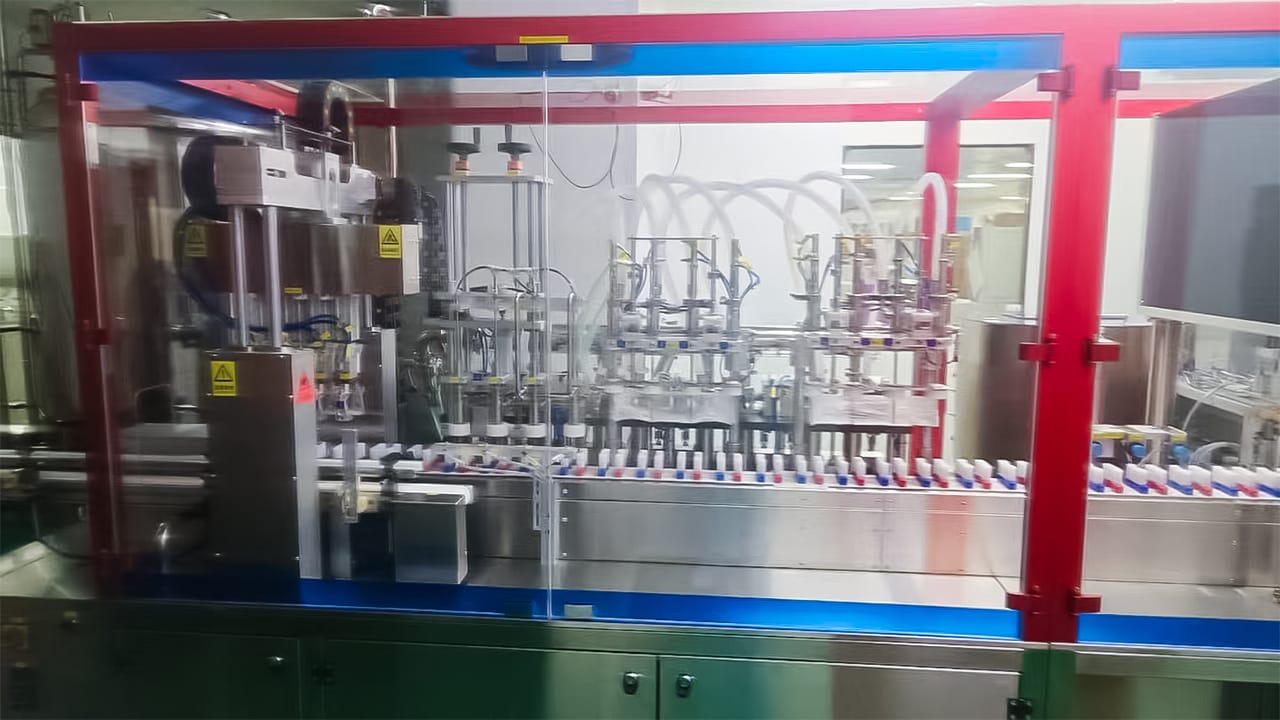

Fully Automatic Filling Lines for Lotion and Cream

Application Scenarios:Creams, Solid Masks, Essences, Cosmetic and Skin Care Products.

Fully Automatic Filling & Packaging Lines for Cosmetics

Application Scenarios:Lotions, Toiletries, Creams, Solid Masks, Essences.

TRPACK's Recommended Products

TR-LP Series Automatic 500ML Bottle Unscrambler Machine

The LP Series(for 500ml bottles) Fully Automatic Bottle Unscrambler is an integrated mechanical and electrical device. It is easy to operate and maintain, and provides reliable performance. It is equipped with a quantitative control detection device for bottle discharge and an overload protection device.

This machine is fully intelligent, and the noise level is less than 70 dB. All of the machine’s materials are made of high-quality 304 stainless steel, meeting GMP requirements. The mechanical reverse bottle correction mechanism unifies the bottle mouths. It is also equipped with a bottle storage device which greatly improves production efficiency. The machine has three stepless speed regulating motors. One of these is used to adjust the speed of the bottle sorting disk.

The faster the speed of the bottle sorting disk, the faster the bottle discharge speed; conversely, it will be slower. At the outlet of the machine, an Optonix photoelectric switch detects the presence of full bottles on the subsequent conveyor belt. If this occurs, the bottle sorting disk motor will automatically stop. If a shortage of bottles is detected, the motor will automatically start again.

TR-XJP Automatic Rotary Bottle Turntable

The TR-XJP Rotary Bottle Turntable is an automatic bottle feeding platform that uses variable frequency speed control to ensure empty bottles enter the conveyor in sequence. It is an ideal alternative to manual operations. This equipment has a simple structure and can handle both small and large bottles without the need for part replacement; adjustment is sufficient. It is relatively ideal auxiliary production line equipment in China.

Automatic Intelligent Bottle Gripper

TRPACK Bottle Gripper is an automatic mechanical hand loading mold equipment (an intelligent turnover basket conveying system). The operator places the full bottle turnover baskets, and after the baskets are removed, the empty turnover baskets are automatically collected.

TR-ZL Fully Automatic Spider Hand Bottle Unscrambler

TRPACK’s TR-ZL fully automatic spider hand bottle unscramblerus uses the most advanced and stable robotic arm method to automatically arrange the disordered bottles in an orderly manner onto the conveyor belt. Firstly, the coordinates and axis data of each bottle are transmitted to the robotic arm system through the Cognex vision detection system. Then, the robotic arm automatically picks up and places the bottles onto the conveyor.