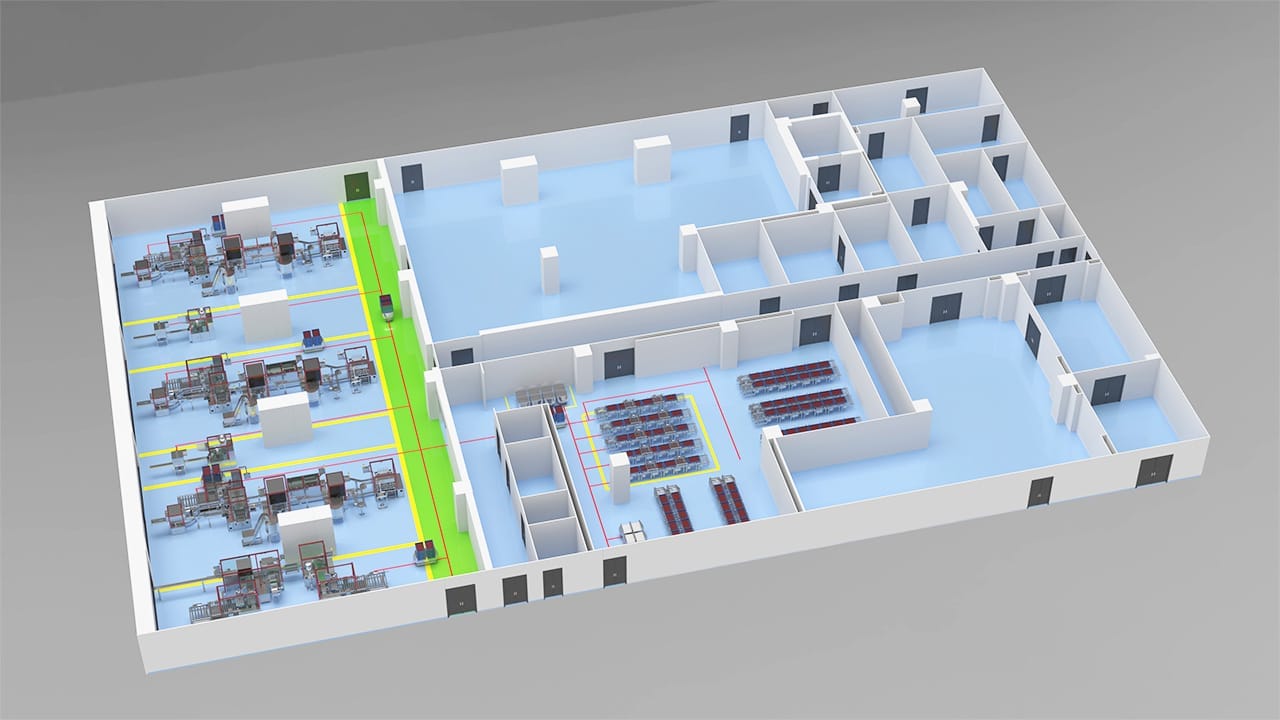

Welcome to the TRPACK Global Intelligent Packaging Case Study Center.

As a professional manufacturer and supplier of cosmetic and daily chemical production lines, TRPACK adheres to innovation as its foundation, driven by industry pain points and customer needs. We possess an industry-leading R&D team and advanced technology, integrating equipment across all stages of the packaging line to solve your comprehensive process from filling, capping, sealing, labeling to carton packing and box packaging.

Below are TRPACK's high-quality, successful project case studies, showcasing projects executed to strict standards, primarily covering EPC turnkey projects; the cosmetics industry; the personal care industry; the household cleaning industry; the oral care industry; and the pharmaceutical industry.

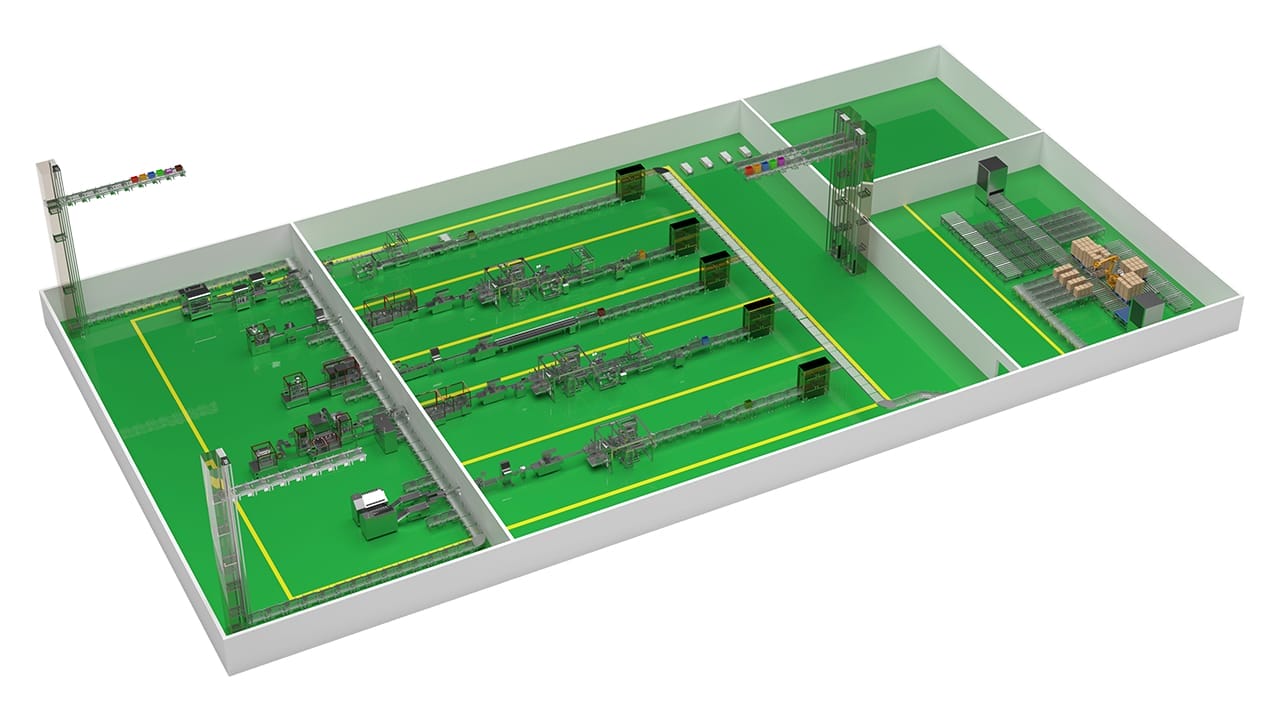

EPC Turnkey Lines

Case 1

-

Related Equipment:

Emulsion Line, Cigarette Packer, Case Packer, Case Sealer, Palletizer

-

Application Scenarios:

Essence, Perfume, Moisturizing Water, Toner, Hair Treatment, Sunscreen.

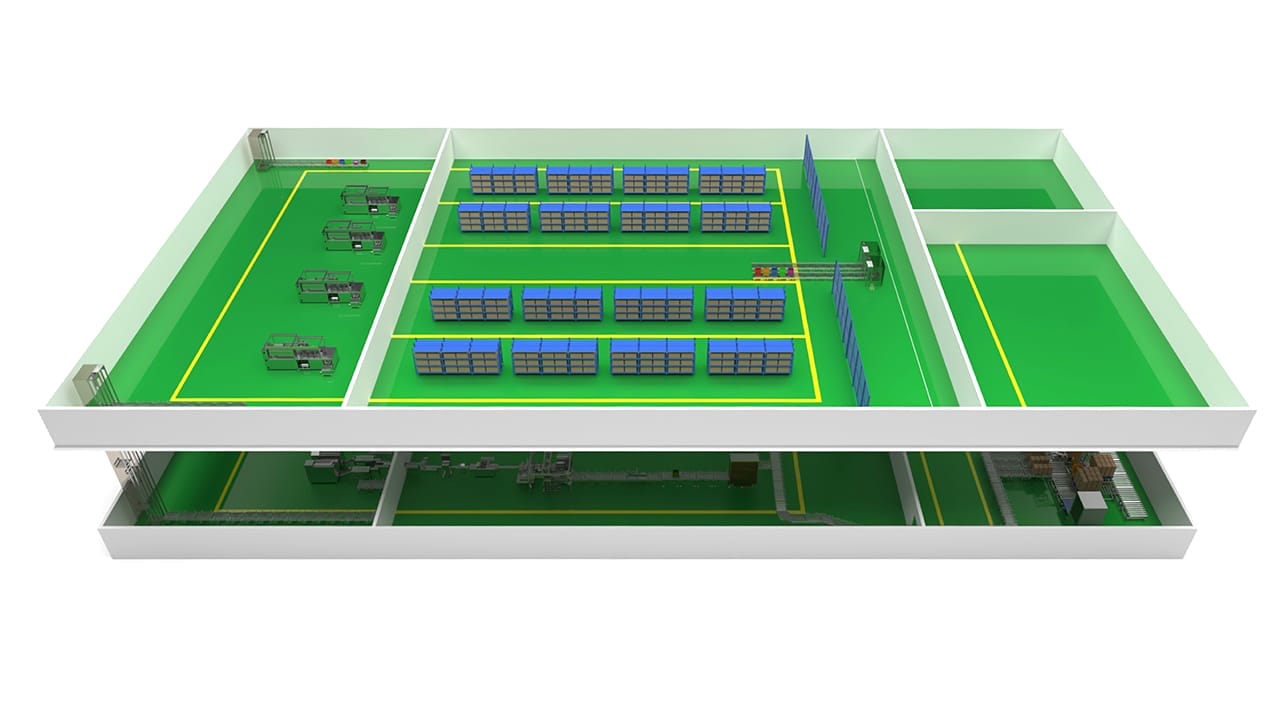

Case 2

-

Related Equipment:

Spider-Hand Bottle Handling Machine, High-Viscosity Filling Machine, Servo Capping Machine.

-

Application Scenarios:

Body Shampoo, Hair Shampoo, Body Lotion, Hair Conditioner.

Case 3

-

Related Equipment:

Avg Transportation Trolley, Bottle Picking And Mold Loading Machine, Water and Lotion Line, Carton Machine.

-

Application Scenarios:

Body Shampoo, Hair Shampoo, Body Lotion, Hair Conditioner.

Cosmetic & Skin Care

Case 1

-

Related Equipment:

Fully Automatic Cream And Lotion Integrated Machine; Automatic Bottle Loading And Unloading Machine.

-

Application Scenarios:

Cream, Solid Facial Mask, Eye Cream.

Case 2

-

Related Equipment:

Fully Automatic Cream and Lotion Production Machine.

-

Application Scenarios:

Creams, Solid Masks, Essence Waters, Personal Care Products .

Case 3

-

Related Equipment:

Fully Automatic Cream and Lotion Production Machine.

-

Application Scenarios:

Creams, Solid Masks, Essence Waters, Lotions, Toiletries.

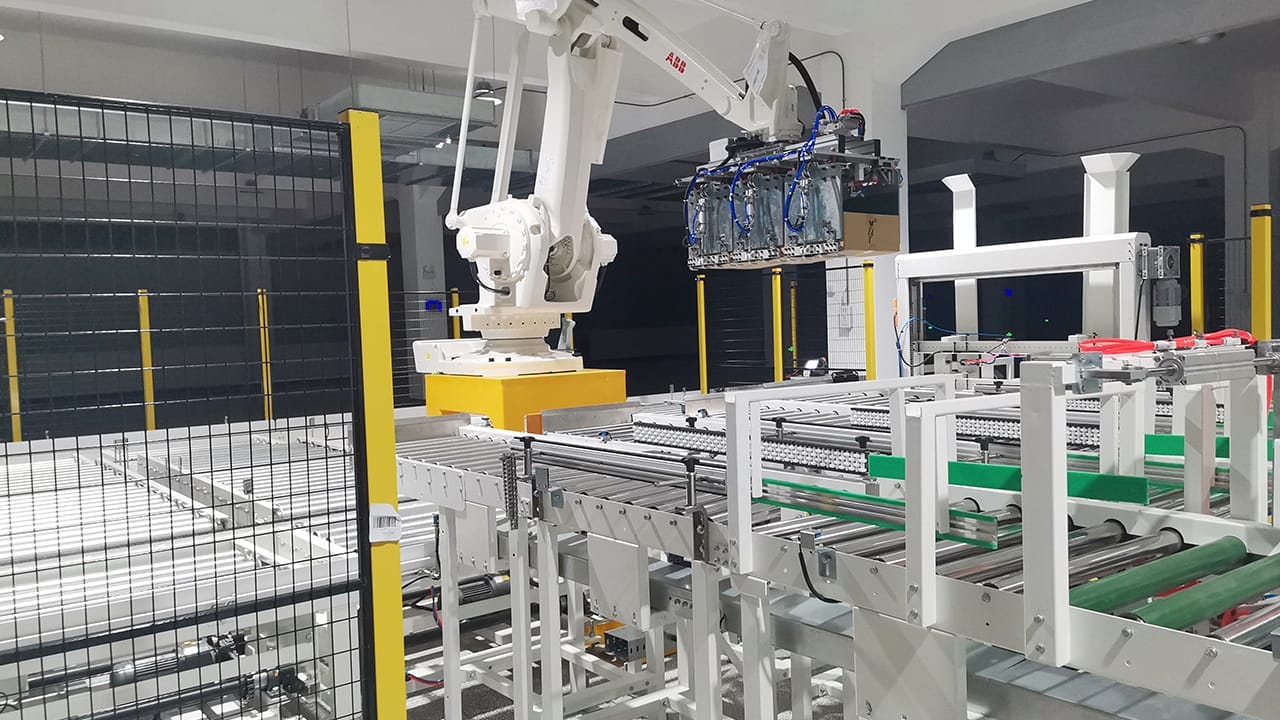

Personal Care

Case 1

-

Related Equipment:

Six-Head Gear Pump Filling Machine, Ten-Head Continuous Cap-Securing Machine, Case Packer, Sealing Machine, Box Labeling Machine, Robot Palletizing Machine.

-

Application Scenarios:

Hair Shampoo, Conditioner, Body Lotion, Hand Sanitizer.

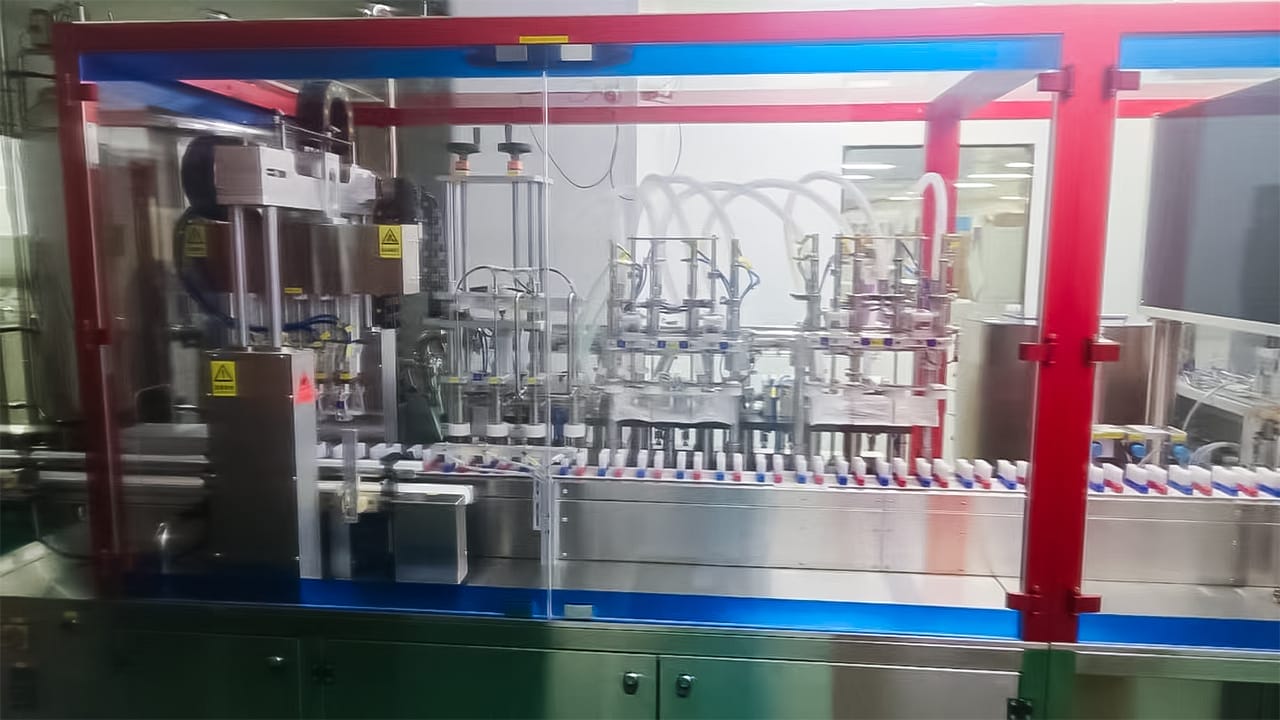

Case 2

-

Related Equipment:

Eight-Head Full-Tracking Filling Machine, Spider-Hand For Removing And Installing Pump Caps Machine, Four-Head Single-Fill Capping Machine, Case Packer, Sealing Machine, Edge Trimming Machine.

-

Application Scenarios:

Hair Shampoo, Hair Conditioner, Body Lotion, Moisturizing Lotion, Hand Sanitizer.

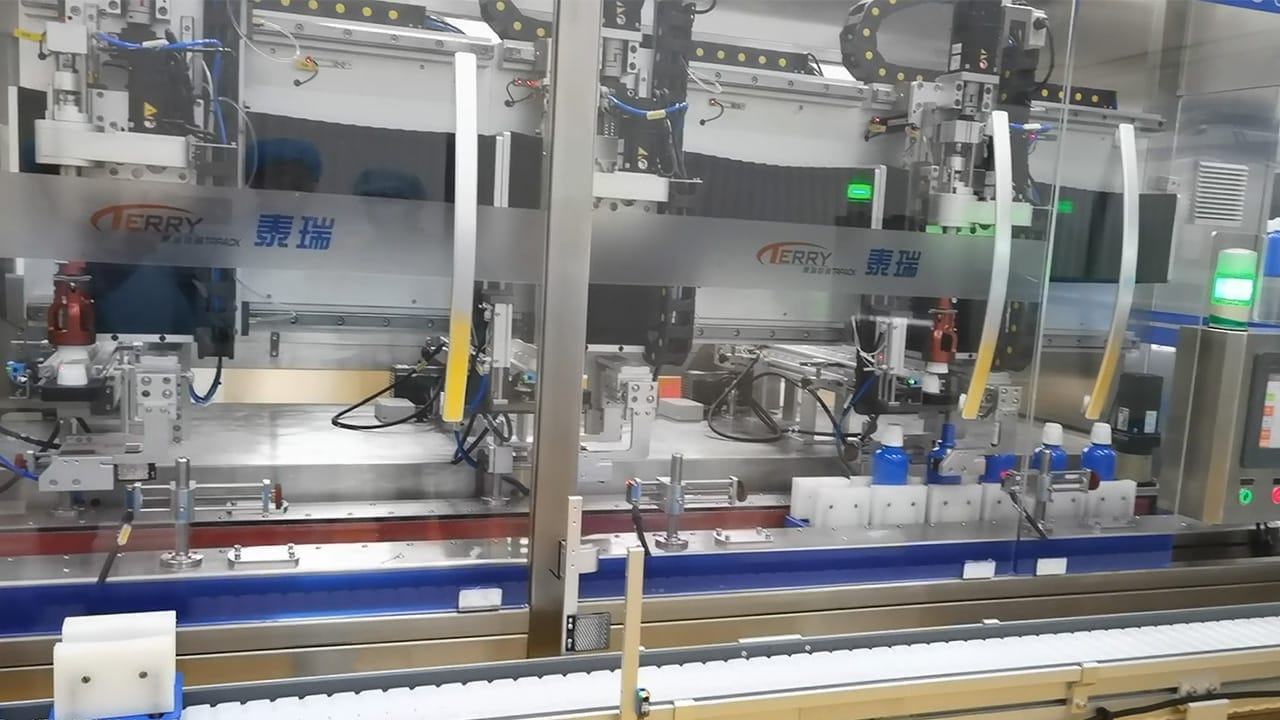

Case 3

-

Related Equipment:

High-Viscosity Filling Machine, Automatic Cap Threading Machine, Automatic Capping Machine.

-

Application Scenarios:

Hair Shampoo, Hair Conditioner, Body Lotion, Moisturizing Lotion, Hand Sanitizer.

Household Cleaning

Case 1

-

Related Equipment:

Atmospheric Pressure Self-Flow Filling Machine, Single-Head Rotary Cap Sealer At Both Ends, Insert-Type Rotary Cap Sealer, Aluminum Foil Sealing Machine.

-

Application Scenarios:

Laundry Detergent, Dishwashing Liquid, Floor Cleaner, Gold Silk Clothing Softener.

Case 2

-

Related Equipment:

Six-Head Gear Pump Attached to the Filling Machine; Insertion-Type Pump Cover Capping Machine.

-

Application Scenarios:

Dishwashing Liquid, Kitchen Grease Remover, Laundry Detergent, Household Cleaner.

Case 3

-

Related Equipment:

Eight-Head Tracking Anti-Corrosion Gear Pump Filling Machine, Automatic Top Cover Sorting Loading Machine, Insert-Type Capping Machine.

-

Application Scenarios:

Toilet Cleaner, Grease Remover, Disinfectant and Sterilizing Solution Conditioner.

Oral Hygiene Care

Case 1

-

Related Equipment:

Spider-Hand Bottle Handling and Loading/Unloading Machine, Reverse Suction And Blowing, Atmospheric Self-Flow Filling Machine, Three-Head Single-Head Capping Machine, Face Labeling Machine, Case Packer, Sealing Machine, Palletizing Machine.

-

Application Scenarios:

Mouthwash.

Case 2

-

Related Equipment:

Six-Head Inline Blow AndSuction Machine; Six-Head Full-Length Filling Machine; Two-Head Single-HeadCapping Machine.

-

Application Scenarios:

Mouthwash.

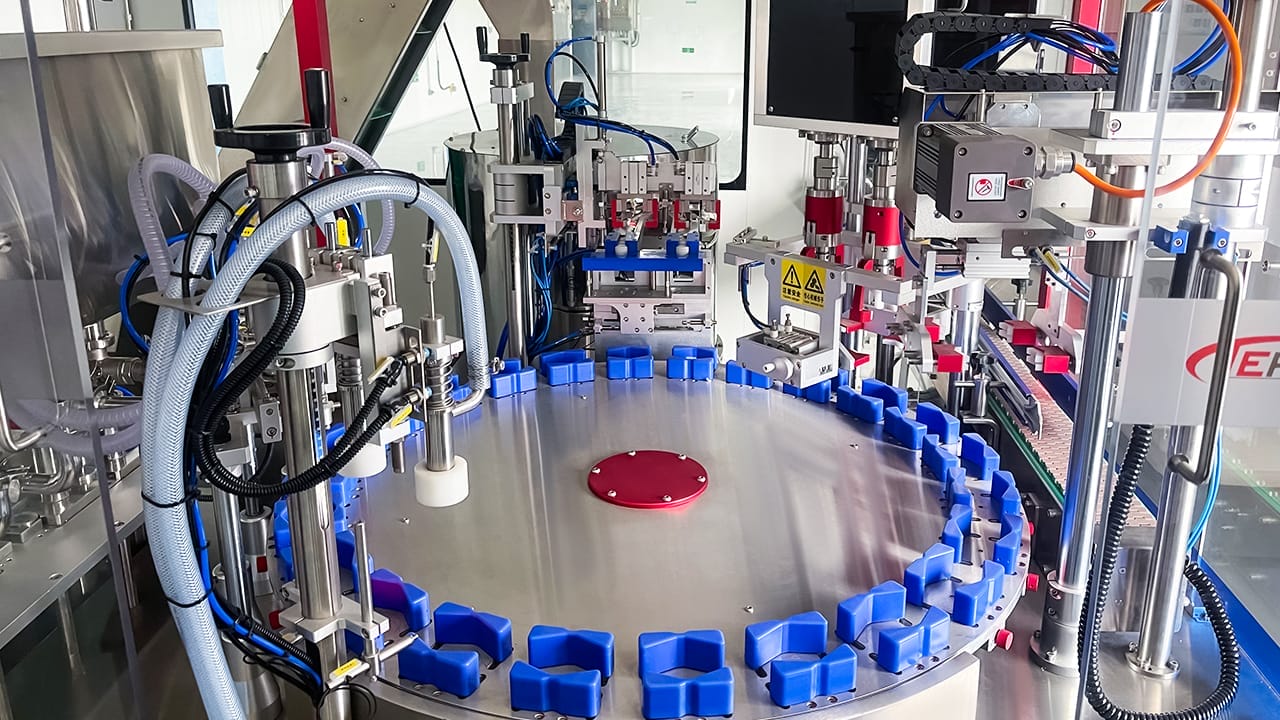

Case 3

-

Related Equipment:

Automatic Tube Feeding Machine, Fully Automatic Turntable Machine, Filling, Capping And Sealing Integrated Machine.

-

Application Scenarios:

Oral Spray, Oral Freshener.

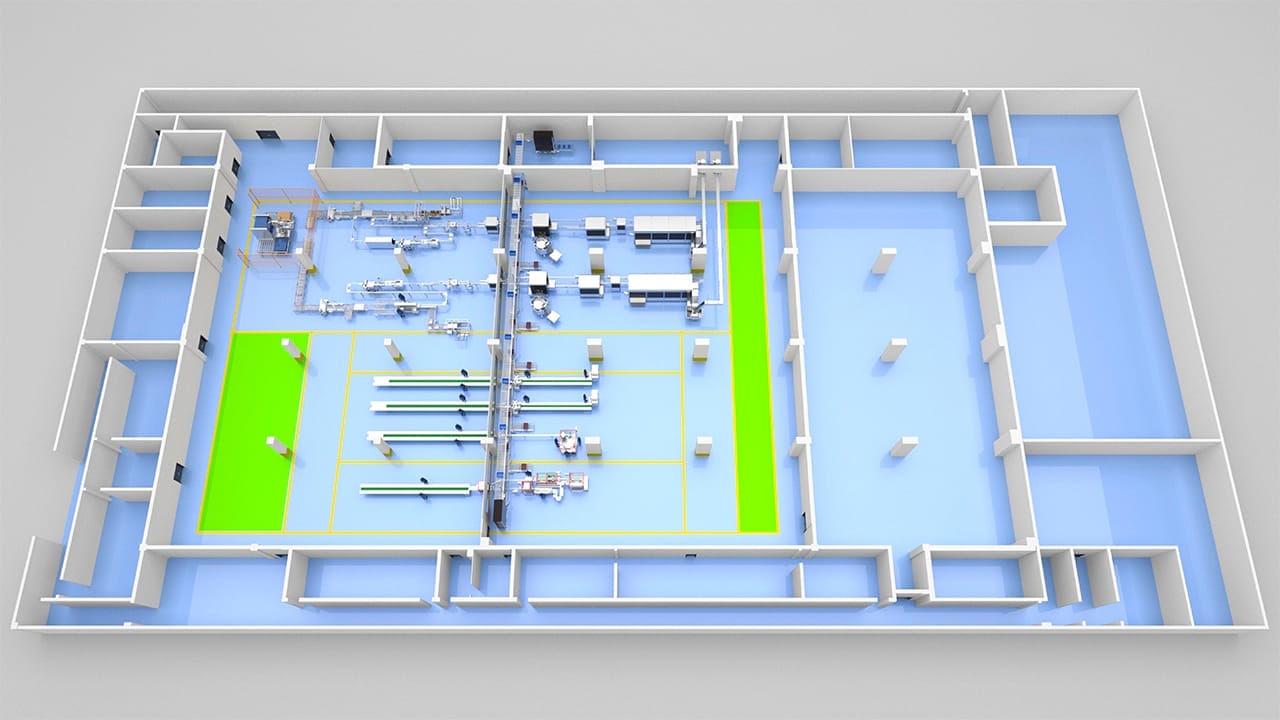

Pharma & Healthcare

Case 1

-

Related Equipment:

Fully Automatic High-Speed Tube Machine; Fully Automatic High-Speed Carton Machine.

-

Application Scenarios:

Facial Cleanser, Hand Cream, Tube Ointment, Eye Cream.

Case 2

-

Related Equipment:

Automatic Bottle Sorting Machine, In-Line Blowing And Suction Machine, Ten-Head Continuous Filling Machine, Bottle Sorting And Butterfly Cap+ Capping Machine.

-

Application Scenarios:

Pharmaceutical Shampoo, Skin Medication Lotion.

Case 3

-

Related Equipment:

Explosion-Proof Electrical Cabinet, Fully Automatic Explosion-Proof Rotary Filling And Capping Integrated Machine.

-

Application Scenarios:

Alcoholic Disinfectants, Alcoholic Hand Sanitizers, Alcoholic Sprays.